US-Plus® Prozesskontrolle

Prozesskontrolle zur Prozessüberwachung und Wareneingangskontrolle

Innovation

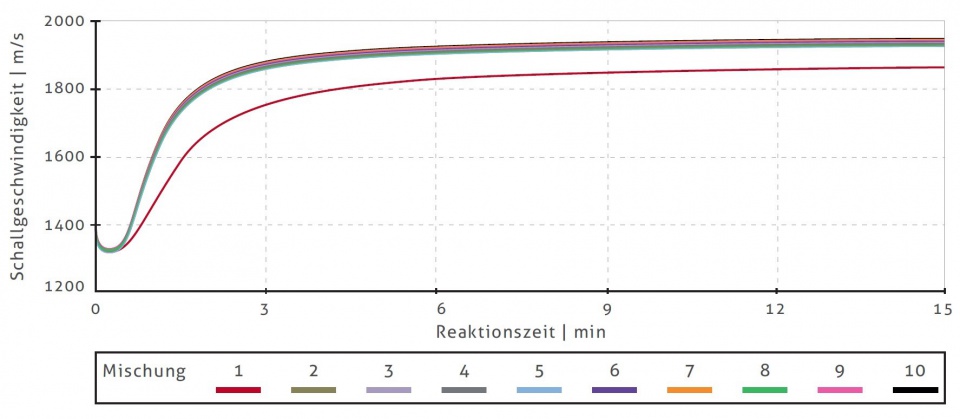

Die innovative Online-Prozesskontrolle GZ US-Plus® ermöglicht die berührungslose Prozessüberwachung zur Aushärtungskontrolle an vernetzenden Kunststoffen wie beispielsweise Verbundwerkstoffe (glasfaser- und kohlefaserverstärkte Kunststoffe), rieselfähige Granulate, Gießharze, BMC/SMC, Klebstoffe (Epoxidharze) etc. Die Funktionsweise der Online-Prozesskontrolle basiert auf Ultraschallmessungen. GZ US-Plus® gestattet Aussagen über Unterschiede in den Aushärteeigenschaften und im Fließverhalten im Vergleich zu Referenzwerten oder anderen Chargen sowie über Abweichungen in Produktionsparametern. Über die Analyse der Messdaten lassen sich die optimalen Prozessparameter ermitteln. So können Aushärtezeiten minimiert, Ausschuss vermieden und die Qualität des Produktionsprozesses dokumentiert werden.

Zuverlässigkeit

Die Zuverlässigkeit der Methode und Ihre Vorteile wurden in einer Vielzahl von Studien und Vergleichsversuchen mit anderen Verfahren wie der dynamisch-mechanischen Analyse (DMA), der dynamischen Differenzkalorimetrie (DSC) oder der Rheologie sowohl in der Industrie als auch an der Bundesanstalt für Materialforschung und -prüfung (BAM) nachgewiesen. Die Online-Prozesskontrolle wird inzwischen seit über 20 Jahren erfolgreich in der Industrie und Forschung eingesetzt.

Vorgehensweise zur Eignungsprüfung

-

Prüfung

Prüfung der Einsetzbarkeit der US-Plus® Technologie für das kundenspezifische Material

-

Vorversuche

Durchführung von günstigen Vorversuchen an kleinen Materialmengen in unserem akkreditierten Materialprüflabor

-

Anmietung

Anmietung des Analysegeräts zur Durchführung von Vor-Ort-Messungen für einen begrenzten Zeitraum

-

Erwerb des Analysegeräts

Erwerb des Analysegeräts US-Plus® zur Wareneingangs- bzw. Prozesskontrolle

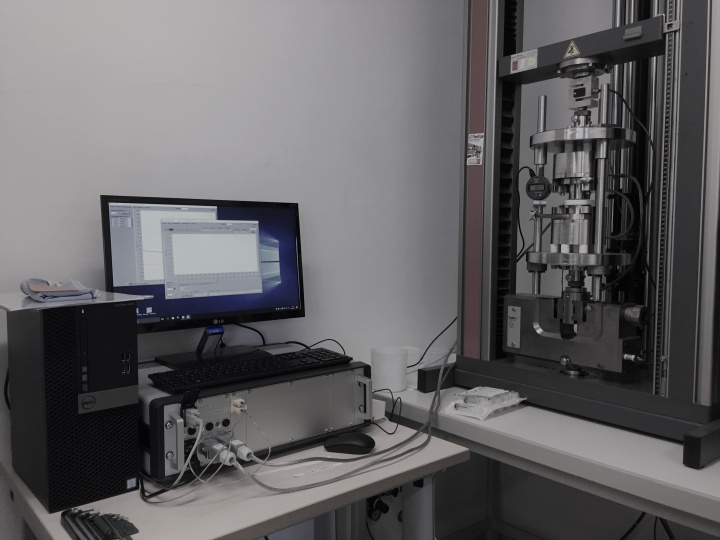

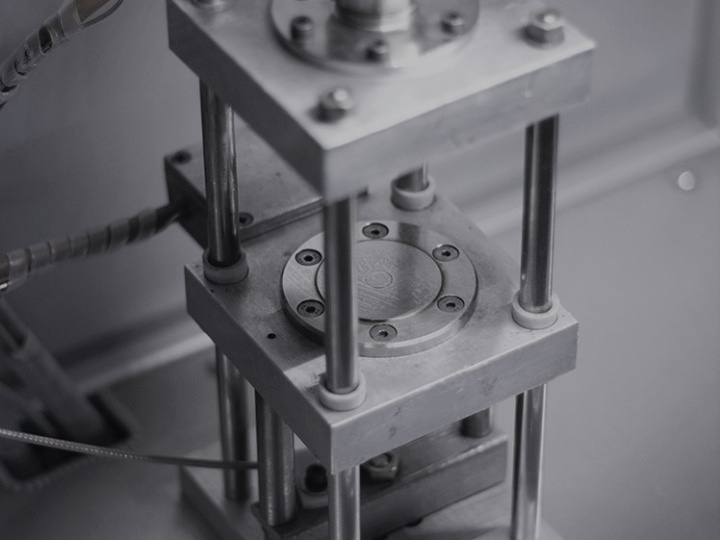

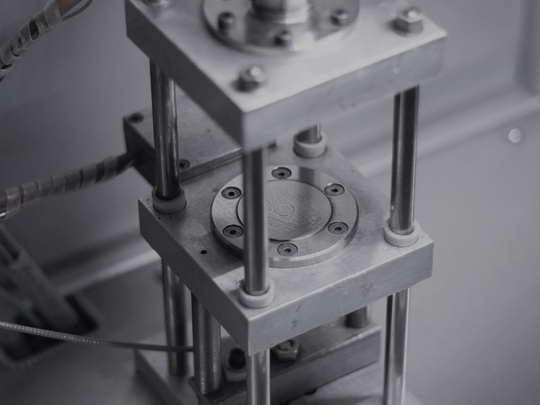

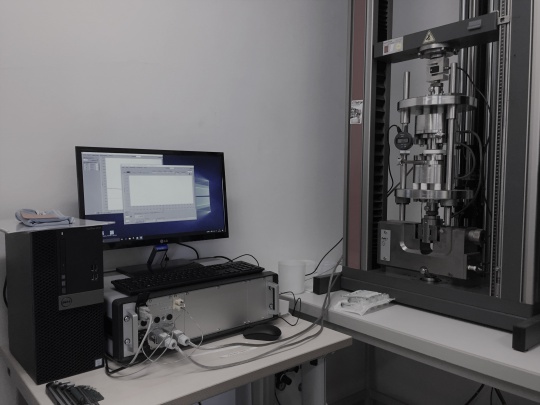

US-Plus® Analysegerät

Das US-Plus® Analysegerät besteht aus einem leistungsfähigen Ultraschallerzeuger und einem Industrie-PC. Das Gerät wird zusammen mit Ultraschallprüfköpfen eingesetzt, die fest in ein Werkzeug oder eine Heizpresse eingebaut werden. Über impedanz-optimierte Sensorkabel werden die Ultraschallsensoren mit dem Analysegerät verbunden.

Optional sind eine Heizpresse, ein I/O-Modul für die Werkzeugschnittstelle und ein Temperaturregler erhältlich. Die Prüfköpfe sind in der Standard-Version bis 180 °C und in der Hochtemperatur-Version bis 250 °C einsetzbar.

- Einsatz in der Produktion, im Wareneingang, in der Qualitätssicherung und der Forschung & Entwicklung

- Kontrolle von Transport- und Lagerungsbedingungen (Vorhärtung, thermischer Abbau, etc.)

- Erfassung von Fließfronten

- Schnelle Kontrolle von Chargen und Mischansätzen, z.B. im Wareneingang, innerhalb weniger Minuten

- Direktes Erkennen von Mischfehlern vor der Herstellung zur Produktionsfreigabe

- Prüfung von Mischungsverhältnissen

- Optimierung von Prozessparametern

- Möglichkeit des Online-Prozessmonitorings direkt im Werkzeug

US-Plus® Prüfdienstleistung

Mittels der innovativen Online-Prozesskontrolle GZ US-Plus® können im Kundenauftrag Prüfdienstleistungen zur Untersuchung des Aushärteverhaltens an vernetzenden Kunststoffen wie beispielsweise Verbundwerkstoffe (glasfaser- und kohlefaserverstärkte Kunststoffe), rieselfähige Granulate, Gießharze, BMC/SMC, Klebstoffe (Epoxidharze) etc. durchgeführt werden.

Für die Durchführung von Materialuntersuchungen im akkreditierten Prüflabor (ISO 17025) werden durch den Auftraggeber Mustermengen des zu untersuchenden Materials beigestellt. Nach Abschluß der Prüfdienstleistung wird ein aussagekräftiger Prüfbericht inkl. einer umfangreicher Dokumentation der durchgeführten Messungen erstellt. Die Prüfdienstleistung kann für produktionsbegleitende Messungen oder zur Optimierung der Prozessparameter (Temperatur, Zeit, Mischungsverhältnisse, etc.) durchgeführt werden.

US-Plus® Mietgerät

Oftmals sind die Herausforderungen, Anwendungsbedingungen und Aufgaben an eine Prozesskontrolle sehr unterschiedlich. Aus diesem Grund ist die Online-Prozesskontrolle GZ US-Plus® zur Prüfung der Anwendbarkeit auch als Mietgerät erhältlich. Das Meß- und Analysegerät ist mit einer integrierten Heizpresse ausgestattet und kann sowohl im Analyselabor als auch direkt in der Produktion zu Untersuchungen des Aushärteverlaufs eingesetzt werden. Dabei kann das Gerät zur Wareneingangskontrolle, zur Fertigungsfreigabe oder zur Optimierung der Prozessparameter verwendet werden.

Eine ausführliche eintägige Einweisung des Bedienpersonals in die Hard- und Software vor Ort sowie ein telefonischer Support während der Mietdauer gehören immer zum Angebot. Bei anschließendem Erwerb des Analysegeräts werden die Mietkosten zum Teil auf den Kaufpreis angerechnet. Die Mindestmietdauer beträgt zwei Monate.

Anfrage Formular

Bitte füllen Sie für die Zusendung eines Angebotes das nachfolgende Formular aus. Bei Abweichungen oder speziellen Konfigurationswünschen verwenden Sie bitte das Kommentarfeld. Nach Versand der Anfrage erhalten Sie von uns zeitnah ein unverbindliches Angebot sowie weitere Informationen.

Ihr Ansprechpartner

Dipl.-Ing. (FH) Matthias Grimm

Leiter Prozesskontrolle

+49 30 7790791-51

matthias.grimm@grassezur.de