Composite Biegeprüfungen

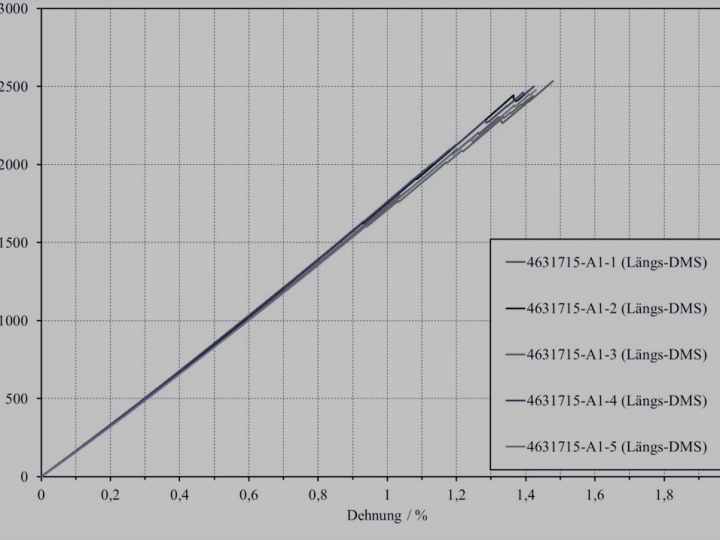

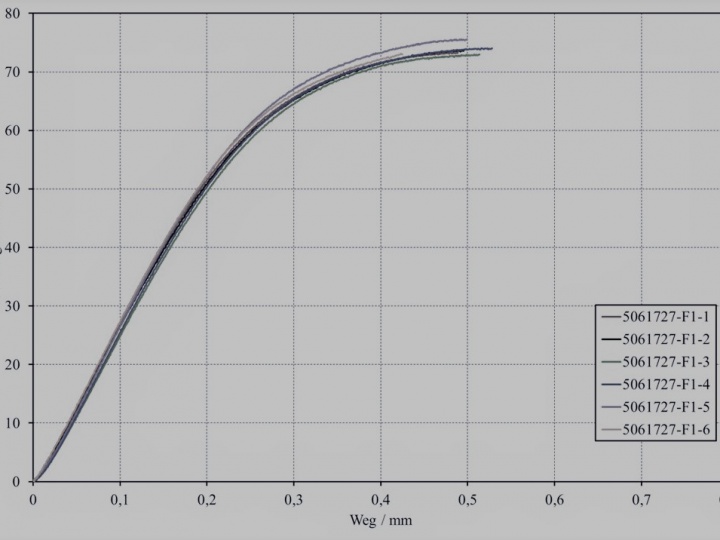

Für die Biegeprüfung an faserverstärkten Kunststoffen (FVK) und an Sandwichstrukturen (Kernverbunden) werden meist die Verfahren nach DIN EN ISO 14125, DIN EN ISO 178 und DIN 53293 verwendet. Es kann eine 3-Punkt oder 4-Punkt-Belastung im Biegeversuch zum Einsatz kommen. Mittels der verschiedenen Prüfverfahren für FVK werden die Biegefestigkeit und der Biegemodul unter einer Biegebeanspruchung der Probe bei definierten Prüfbedingungen ermittelt. Das Prinzip der Biegeprüfung besteht in einer zweiteiligen Biegevorrichtung, in der der Probekörper als Biegebalken zwischen zwei äußeren Auflagern eingespannt und über ein (3-Punkt) oder zwei (4-Punkt) innere Auflager belastet wird. Die Prüfung erfolgt bei konstanter Geschwindigkeit bis zu einer vorgegebenen Verformung oder bis zum Versagen der Probe. Als Ergebnis werden die Biegespannung und der Biegemodul ermittelt.

Bei der Beanspruchung von Composite- oder Sandwich-Material auf 4-Punkt-Biegung stellt sich zwischen den inneren Auflagern ein über die Probekörperlänge konstanter Dehnungs- und Biegeverlauf ein, was ein Vorteil gegenüber dem 3-Punkt-Biegeversuch darstellt. Es ist zu beachten, dass beim 4-Punkt- Biegeversuch zwischen den äußeren und den inneren Auflagern eine zusätzliche Schubbeanspruchung auftritt. Die Auflagerabstände, d.h. die Hebelarme sind so zu wählen, dass die Schubfestigkeit des Werkstoffs unterschritten wird. Der Prüfbereich zwischen den inneren Auflagern ist frei von Schubspannungen.