Composite Zugprüfungen

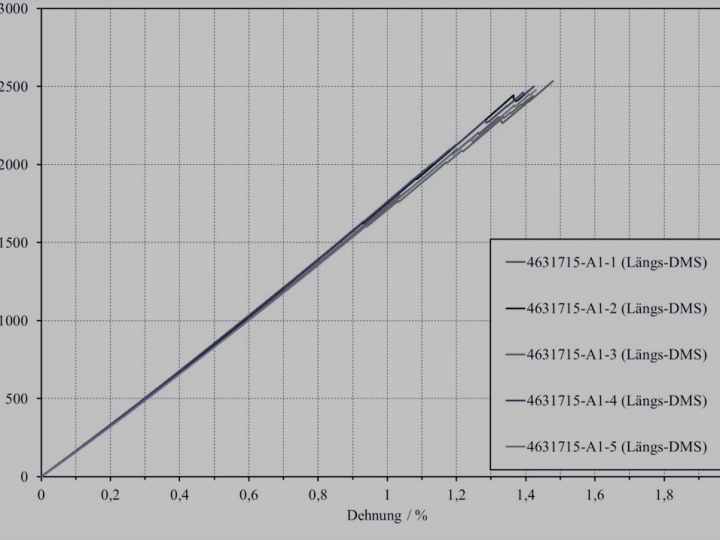

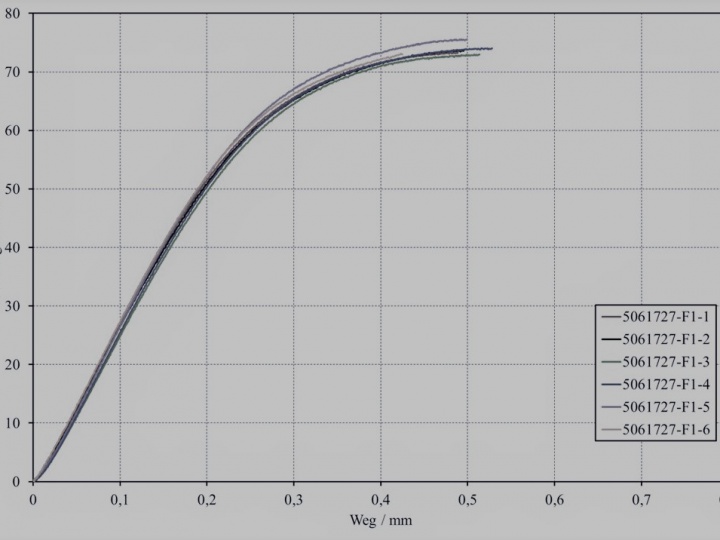

Im Zugversuch werden die mechanischen Werkstoffkennwerte unter quasi-statischer Zugbelastung ermittelt. Der Zugversuch gehört zu den am häufigsten durchgeführten Prüfverfahren und wird auch für Composite-Werkstoffe wie kohlenstoff- oder glasfaserverstärkte Kunststoffe angewendet. Grundsätzlich wird zwischen isotropen, anisotropen und orthotropen Werkstoffen unterschieden. Bei anisotropen Werkstoffen ergibt sich in Faserlängsrichtung (0°-Faserorientierung) eine Faserbruchbelastung (FB) und in Faserquerrichtung (90°-Faserorientierung) eine Zwischenfaserbruchbelastung (ZFB).

Um qualitativ hochwertige Versuchsergebnisse zu erhalten, ist bei diesem Prüfverfahren eine präzise Probekörperfertigung von großer Bedeutung. Aufdoppler mit einer Faserorientierung von +/-45° verhindern ein unerwünschtes Versagen der Probekörper im Einspannbereich (Klemmbruch) aufgrund des Querkraftsprungs. Eine sehr sorgfältige Bearbeitung der Probekörperränder ist sicherzustellen, um komplexe Spannungssituationen und eine frühzeitige Rissinitiierung zu vermeiden. Die Verwendung von Diamantsägeblättern oder CNC-Fräsmaschinen gehört zum aktuellen Stand der Technik. Für die Durchführung der Prüfungen bei erhöhten Temperaturen sind angepasste Klebstoffe für die Aufdoppler und die Dehnungsmeßstreifen zu verwenden.