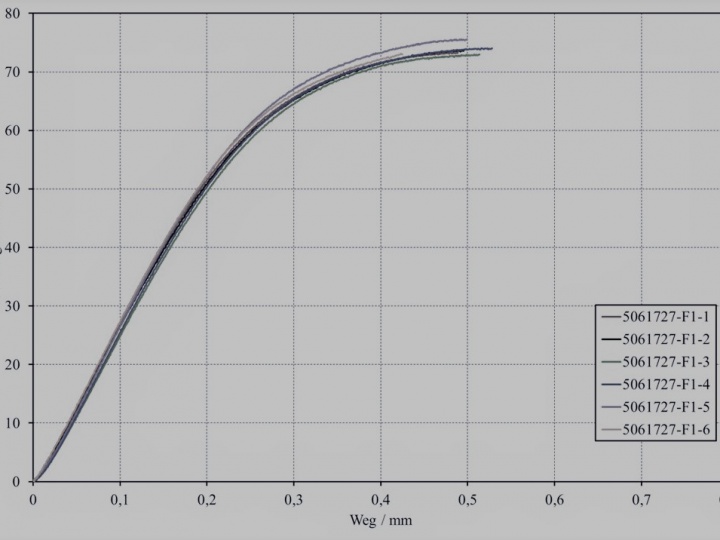

Composite ILSS Tests

ILSS test according to DIN EN 2563

The Short Bend Test Method for Determining Apparent Interlaminar Shear Strength (ILSS) is a modification of the 3-point bend test. The bearing distance is small in relation to the specimen thickness, whereby the specimen is subjected to shear stress. The specimen is a short bar made of a thermosetting or thermosetting matrix with a fiber reinforcement in the 0 ° or 0 ° / 90 ° direction. With apparent interlaminar shear strength, the standard refers to “the maximum shear stress in half the thickness of the specimen at the moment of the first failure”.

The standard indicates limitations of this test method. Depending on the material selection, “the result may be influenced by various couplings such as elongation/bending/twisting etc”. It is possible that the specimen will fail due to bending or plastic deformation. A statement about the actual shear stress at the moment of failure is then not possible. To determine constructive sizes, the method is unsuitable. However, it can be used for material preselection or for quality control. The calculated value is not an absolute value, test results are comparable only within a series. The disadvantage is that the ILSS method requires very small and geometrically simple specimens. With little material expenditure, a qualitative statement about the fiber-matrix bond is generated.