Composite Testing Technology

Our mission

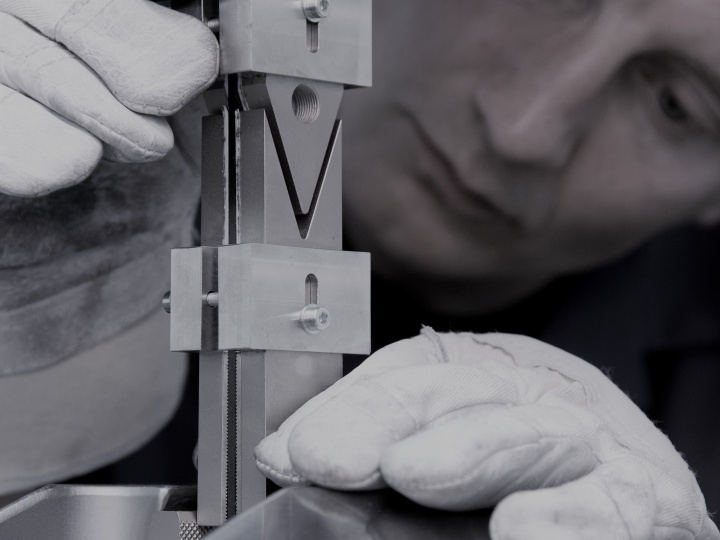

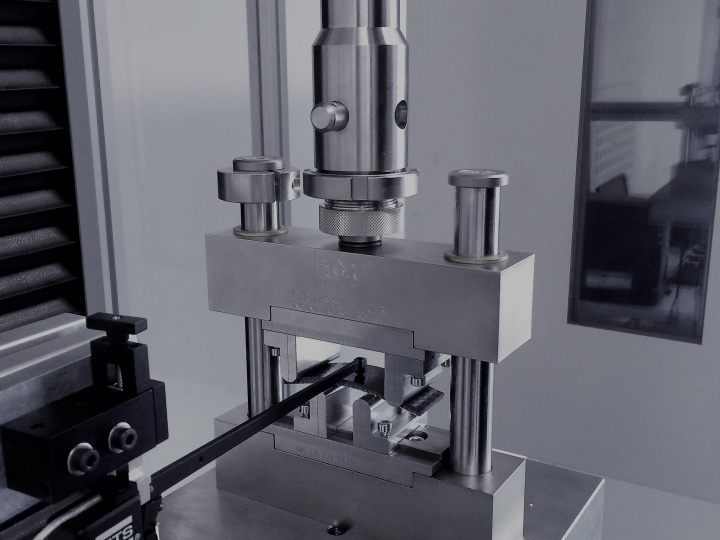

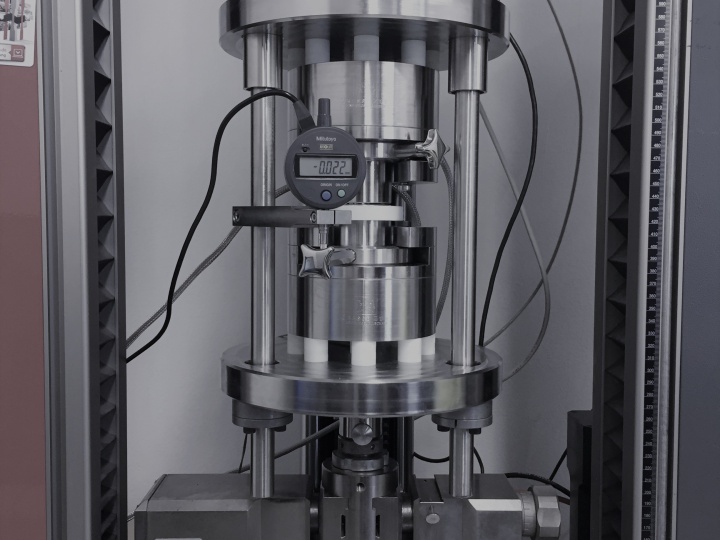

Grasse Zur Composite Testing specialises in the testing of fibre-reinforced plastics and operates an ISO 17025 accredited materials testing laboratory at its site in Berlin. The tests include all relevant procedures in the field of destructive and non-destructive testing and thermal analysis. In addition, the company develops reference test fixtures for material testing, manufactures the online process control GZ US-Plus® for monitoring incoming goods and for production of components made of thermoset plastics and offers professional seminars on all aspects of composite testing in cooperation with experienced lecturers.

Our claim

At Grasse Zur Composite Testing, the quality of material testing for fibre-reinforced plastics is the top priority. The entire team works together to continuously improve the processes in order to guarantee a consistently high quality of material testing. This includes achieving the best test results with the lowest possible standard deviations, testing according to in-house specifications that clearly exceed the requirements specified in the respective test standards, fast and proactive communication with the customers and adherence to the agreed delivery dates with maximum flexibility and fair prices at the same time.

Accredited Testing Services

Reference Test Fixtures

US-Plus® Process Control

Professional Seminars

Composite Testing News

18 January 2023

New dates for professional seminars and training courses 2023 in Berlin

At the beginning of 2023, the well-established professional seminars on the topic of testing fibre-reinforced plastics will take place again in Berlin. The events will be held in compliance with the existing hygiene and protection measures. The number of participants is strictly limited in order to comply with the protective regulations and to ensure the high quality of the training.

If you enter discount in the comment field when booking professional seminars by 15.02.2023, you will receive a discount of EUR 100 per participant. This discount applies to all bookings made by 15.02.2023. Please note that from 01.01.2023 new prices will apply for the specialist seminars and training courses.

25 November 2022

Differences between the thermoanalytical methods DSC and DMA

For many years, Grasse Zur Composite Testing has been carrying out thermoanalytical tests on fibre-reinforced plastics in order to provide clients with information on the curing state of the test specimen material. The materials are usually thermoset plastics made of EP or VE resin systems. Either DSC or DMA analysis is used for the investigations (determination of the glass transition temperature, the degree of curing, the melting temperature and the enthalpy of fusion).

Both test methods can be used to determine the current and the maximum glass transition temperature. However, the analysis technique and the test results differ significantly. The article compares the two test methods.

Composite Testing References

Portfolio

Since 2012, Grasse Zur Composite Testing has specialised in the testing of fibre-reinforced plastics. In addition to testing services in the accredited and non-accredited area, the portfolio includes the development and manufacture of test fixtures and complex test benches for component testing, the ultrasound-based online process control GZ US-Plus® as well as professional seminars.

References

Grasse Zur Composite Testing now counts more than 300 clients from the fields of industry and research among its references. The industrial clients are mainly from the aerospace, wind energy, automotive, chemical industries (raw material suppliers such as fibre and resin manufacturers) and defence sectors. The research institutions are universities as well as Fraunhofer institutes.