Composite Test Fixtures

Reference test fixtures for testing composite materials

Reference test fixtures

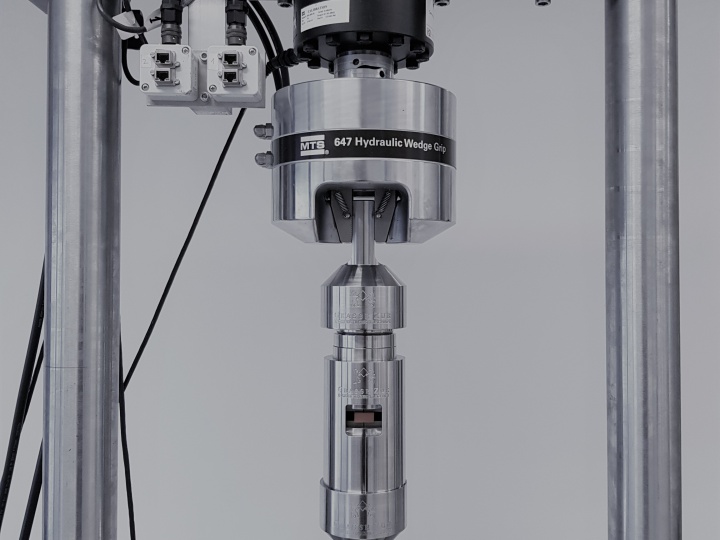

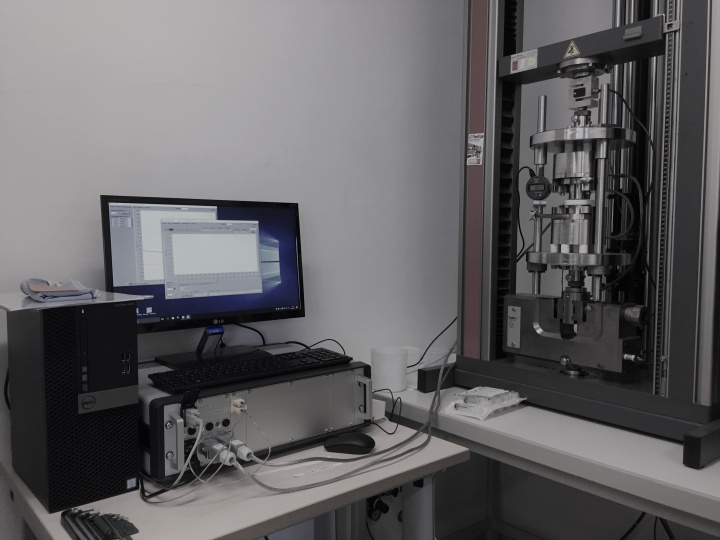

Grasse Zur Composite Testing offers a wide range of test fixtures for the mechanical determination of characteristic values of fibre-reinforced plastics. The test fixtures are used in universal testing machines (e.g. Zwick, MTS, Instron,…) according to the respective test standard to perform quasi-static and cyclic tests. Through the operation of the accredited test laboratory according to DIN EN ISO 17025, Grasse Zur Composite Testing has the know-how in handling test fixtures in order to achieve best test results with optimised ergonomics. As a member of DIN, Grasse Zur Composite Testing actively designs new standards and revises existing test procedures. In addition, individual test devices are developed on behalf of customers, such as the release agent test fixture in cooperation with BMW, with which special applications can be carried out.

Optimised use

The test fixtures are characterised by optimised clamping conditions and alignment possibilities of the specimens as well as easier operation. For this reason, better material properties are achieved with increased reproducibility of the material properties. In addition, new test methods from research and industry, such as the determination of shear characteristic values by means of shear frames from the Federal Institute for Materials Research and Testing (BAM), are transferred to industrial practice and standardised in the corresponding committees, e.g. as DIN EN ISO 20337.

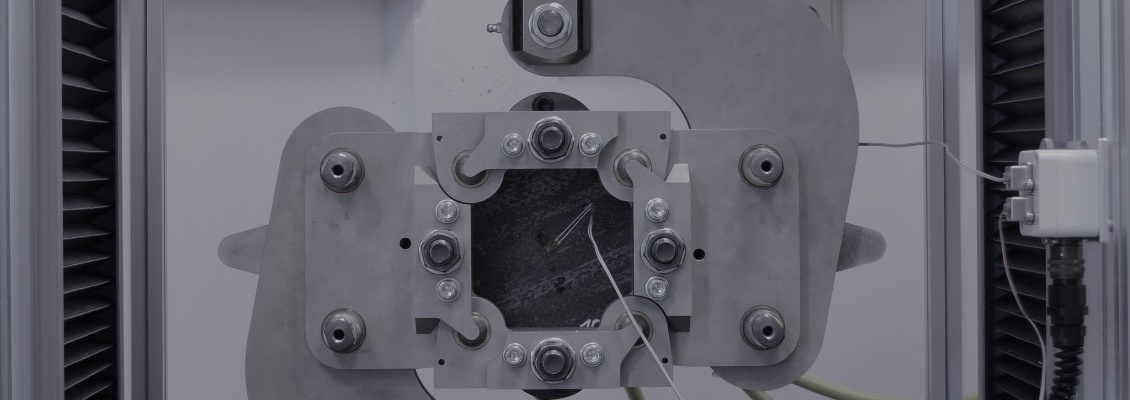

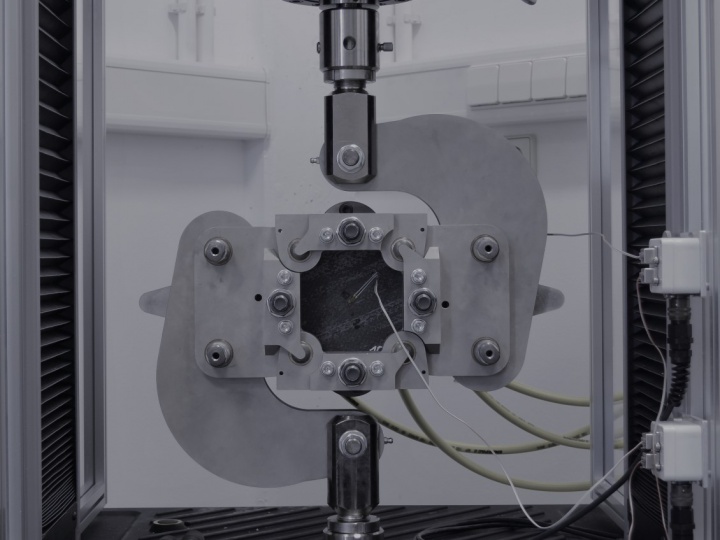

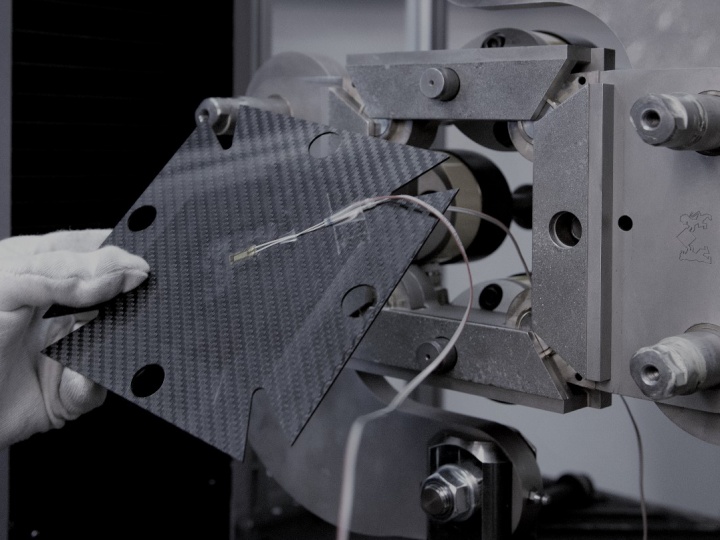

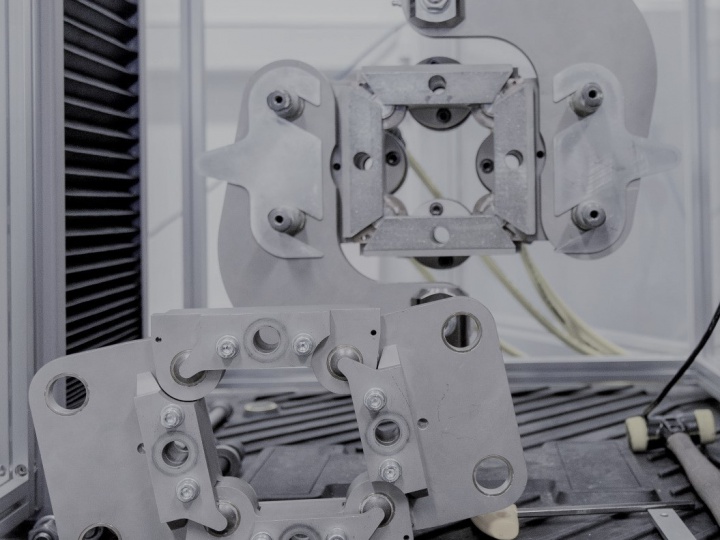

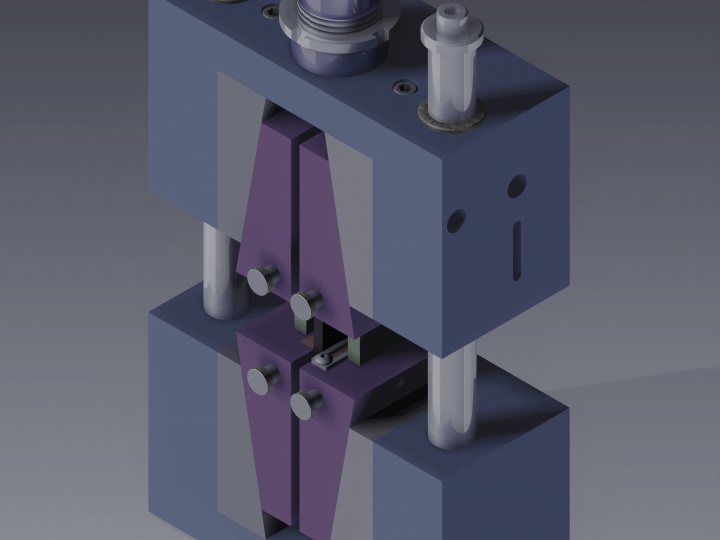

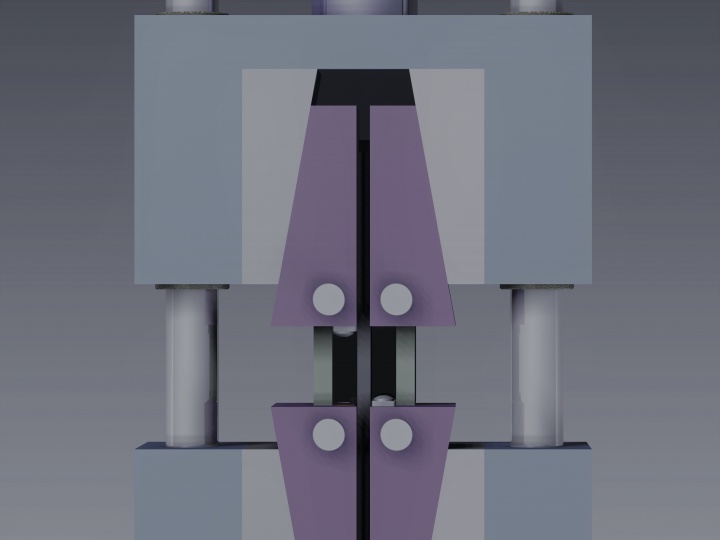

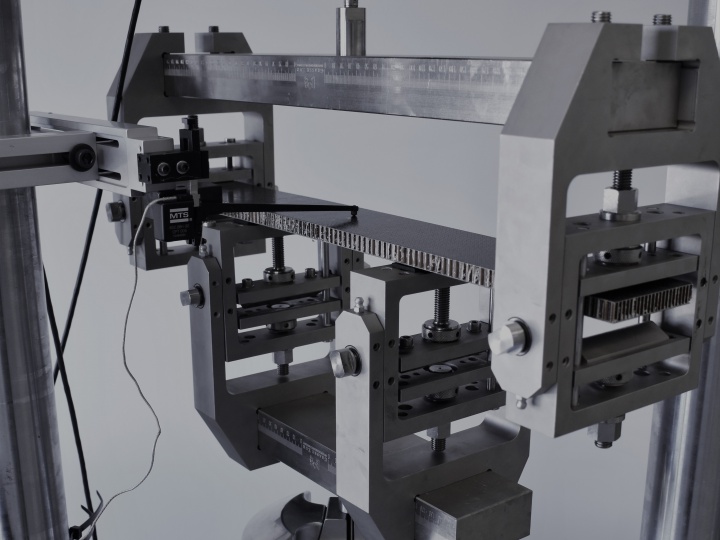

GZ S-100 / S-100 HT

Picture frame shear test system for quasi-static tests

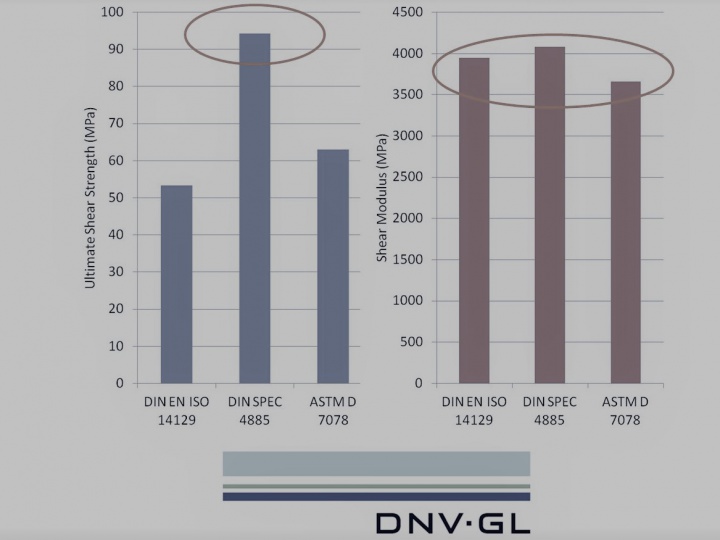

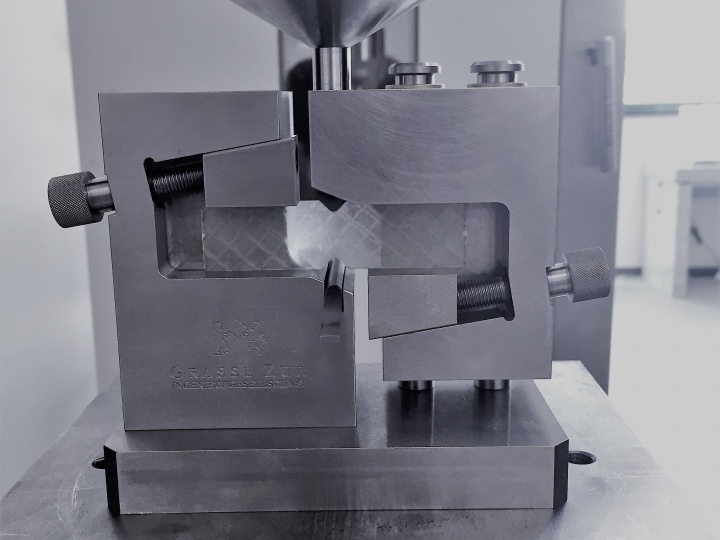

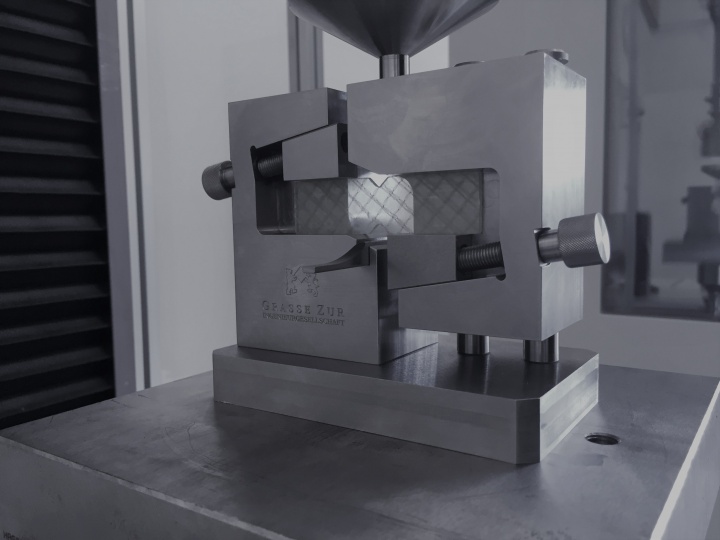

The picture frame shear test system GZ S-100 / GZ S-100HT is an innovative test method for the determination of shear strength and shear stiffness of fibre-reinforced plastics based on a picture frame. The determination of shear characteristics by means of a picture frame represents the reference method for the determination of shear characteristics, is standardised according to DIN EN ISO 20337 (formerly DIN SPEC 4885) and has the approval of the DNVGL for the certification of rotor blades for wind turbines (DNVGL ST-0376).

The picture frame shear test system enables a very precise determination of the shear characteristics of fibre-reinforced plastics (shear strength, shear stiffness and max. shear strain). The test method represents a significantly improved test method compared to all other shear test methods (for example DIN EN ISO 14129, ASTM D7078 or ASTM D5379), since there is a pure state of shear stress in the test specimen. For this reason, significantly higher material characteristic values are achieved with simultaneously lower standard deviations.

The square specimen is clamped hydraulically in the picture frame. Strain gauges are used to determine the shear strain, tabs are not necessary. Due to the split design, a simple and quick change of the test specimen within a few minutes is possible. The biggest advantage of the test method compared to other shear test methods is the non-existing limitation to max. shear strains of five percent, whereby considerably higher shear strengths are achieved. The test method was developed at the Federal Institute for Materials Research and Testing and and has been scientifically validated.

- Shear test system based on a picture frame with a unique possibility for determining the interlaminar shear properties (in-plane shear test)

- Material testing with pure shear stress state

- No free test specimen edges and no notch effects due to surface specimen clamping

- Can be used for tests at elevated temperatures up to +150 °C (GZ S-100 HT)

- Testing of material failure and buckling behavior with test loads up to max. 100 kN

- Hydraulic test specimen clamping with homogeneous clamping distribution with max. 120 kN clamping force

- Testing of isotropic and anisotropic materials with specimen thicknesses up to max. 10 mm

- Can be used in all common universal testing machines

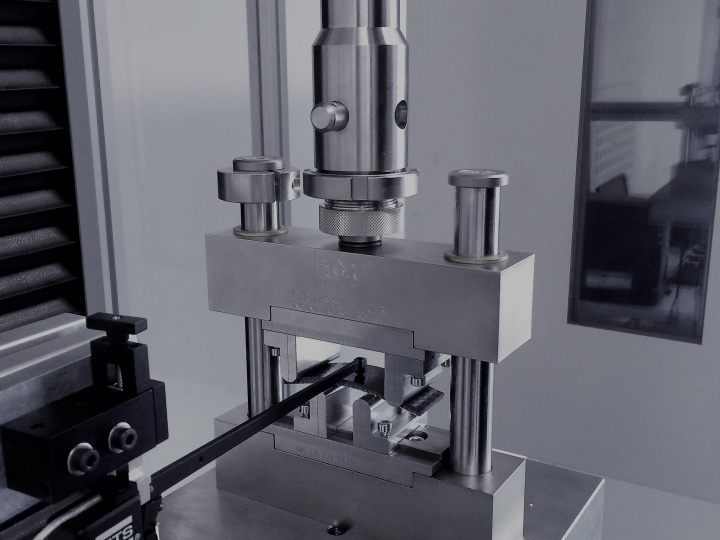

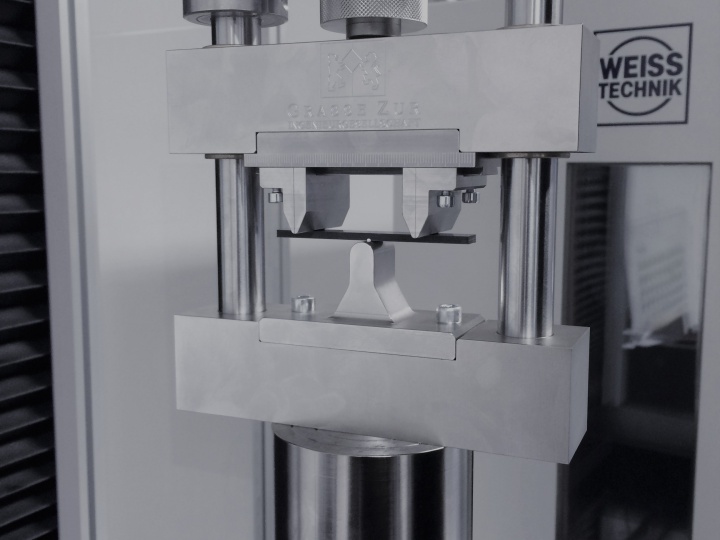

GZ RS-50 / RS-50 H

Rail shear test fixture for quasi-static tests

The rail shear test fixture GZ RS-50 / GZ RS-50 H for specimens with V-shaped notches is suitable for the quasi-static characterisation of the shear properties of fibre-reinforced plastics. The test fixture is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermoset base compounds and is used for unidirectional layers and/or fabrics as well as multilayer composites (sandwich laminates).

The test fixture is characterised by a significantly improved handling compared to similar fixtures. Lateral guides prevent the jaws from slipping out and tilting during specimen changing. Predefined markings allow precise settings for different specimen thicknesses. Positioning facilitates the alignment of the two fixture halves to each other. Precise positioning of the specimen in the test fixture is achieved with a two-axis guide system.

With the hydraulic version GZ RS-50 H, the specimen is clamped by means of a hydraulic clamping jaw system. During the test procedure, the hydraulic system readjusts the clamping force. This ensures that the specimen remains reliably clamped even with decreasing thickness due to load redistribution effects and shear distortion, and that even minimal slipping out is prevented. In addition, the hydraulics ensure an evenly distributed clamping force.

- Maximum test load up to 50 kN

- Substantially simplified test specimen changing compared to comparable fixtures

- Significantly improved accuracy of specimen alignment

- No slipping of the jaws due to lateral guidance

- Significantly increased reproducibility due to biaxial guidance system

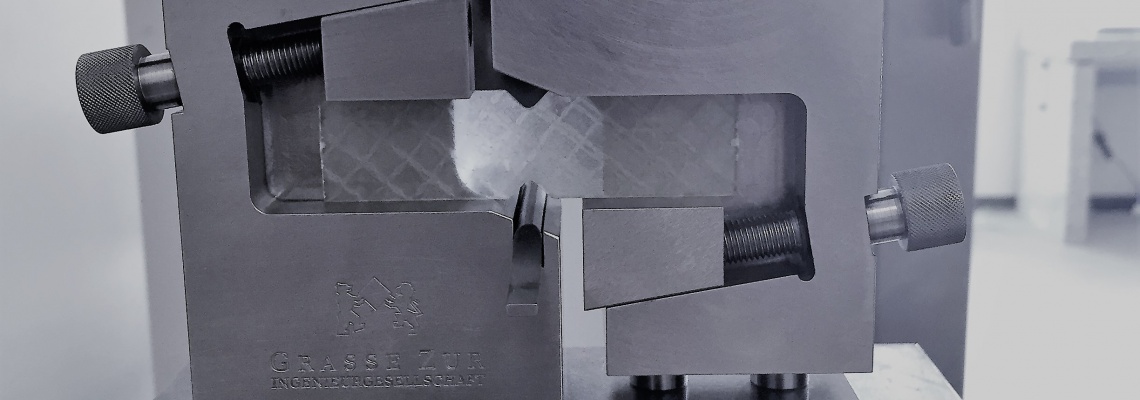

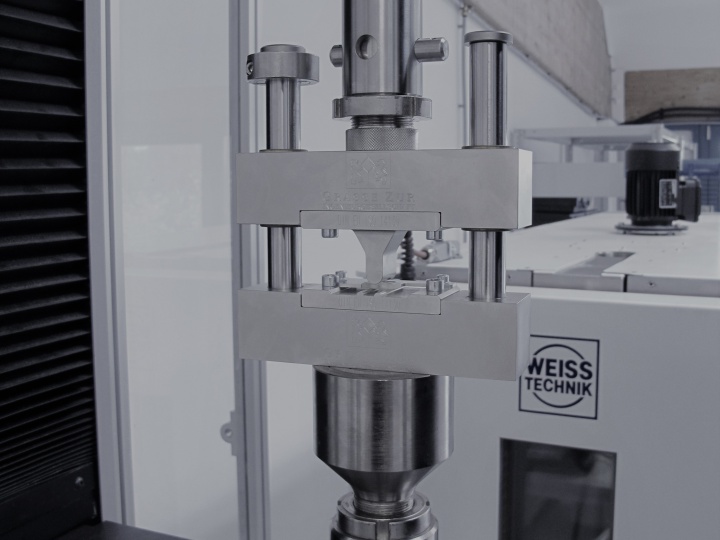

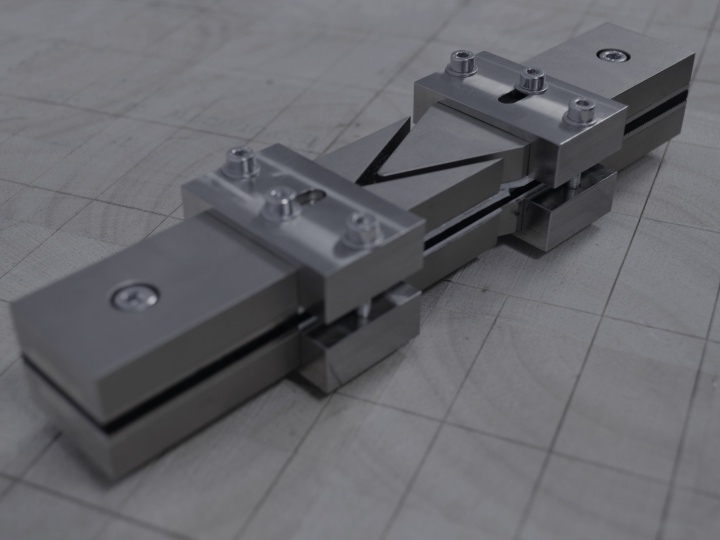

GZ IS-20

Iosipescu shear test fixture for quasi-static testing

For the performance of shear tests according to ASTM D5379, an Iosipescu shear test fixture is used, which can be used in all common universal testing machines. This shear test fixture is suitable for the static characterisation of the shear properties of fibre-reinforced plastics. The Iosipescu shear test is performed by means of an asymmetrically loaded four-point bending specimen. The specimen is clamped in the Iosipescu test fixture and loaded via two profiles that are movable relative to each other. The loads are introduced into the specimen via four areas. A V-shaped notch in the specimen determines the location of the failure. The material load in the specimen represents a shear force shear stress.

A major advantage of the Iosipescu shear test compared to other methods such as the shear tensile test according to DIN EN ISO 14129, the rail shear test according to ASTM D7078 or the picture frame shear test according to DIN EN ISO 20337 is the simple test procedure. With this test method, uniaxially and multiaxially oriented laminates with any fibre orientation can be tested with little effort. However, due to the small specimen geometry and the notch, lower shear characteristics (shear stiffness and shear strength) are usually determined.

- Compact and very high quality test fixture for test loads up to max. 20 kN

- Precise alignment and centring of the specimen by central setting gauge

- Specimen geometry 76 mm x 19 mm x 2...10 mm

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

- Connection to all common electromechanical and servo-hydraulic universal testing machines

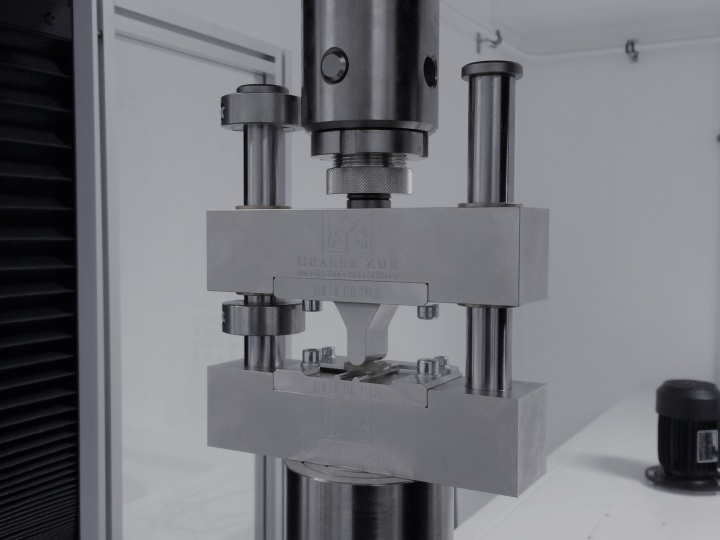

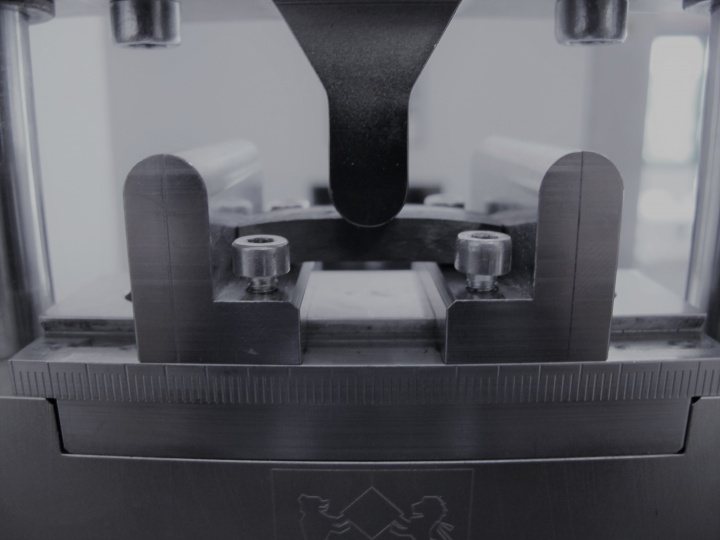

GZ C-20

Celanese compression test fixture for quasi-static testing

The Celanese compression test fixture GZ C-20 is suitable for the quasi-static characterisation of the compression properties of composites according to various standards. The test fixture is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermosetting base materials and is used for unidirectional layers or fabrics. In addition, isotropic materials such as pure resin or adhesive resin materials can also be tested with this test fixture.

The compression test fixture is required for testing fibre-reinforced plastics to prevent the specimen from buckling. With a specimen length of 110 mm, the free test length is only 10 mm. Strain gauges are applied to the centre of the specimen on both sides to determine the compressive strain and buckling. The test fixture consists of clamping wedges which, according to the self-reinforcing principle, divert the axial force of the testing machine into a transverse force for clamping the specimen.

- Stable compression test fixture for static loads up to 20 kN

- Specimen geometry 110 mm x 10 mm x 4/2 mm

- Exchangeable clamping pads for different materials and fibre orientations

- Simple cable feed-through for strain gauges

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

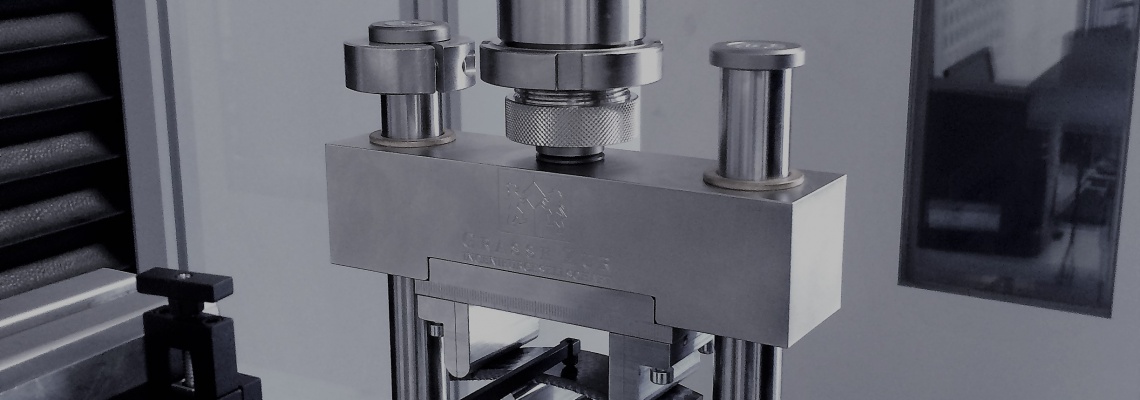

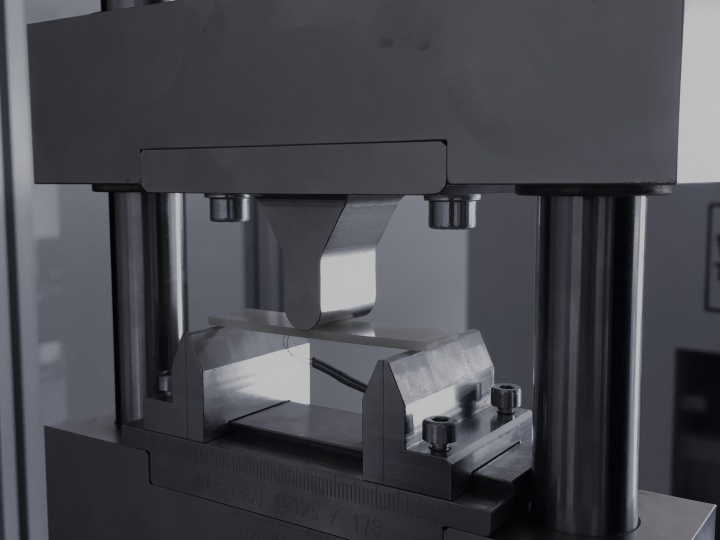

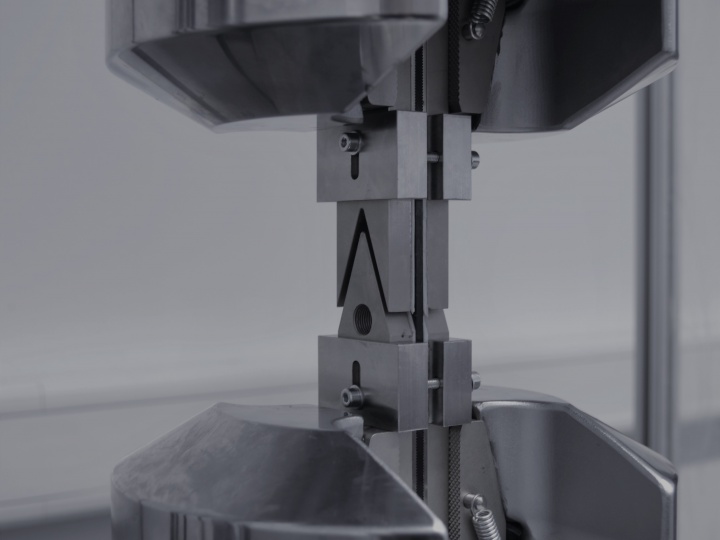

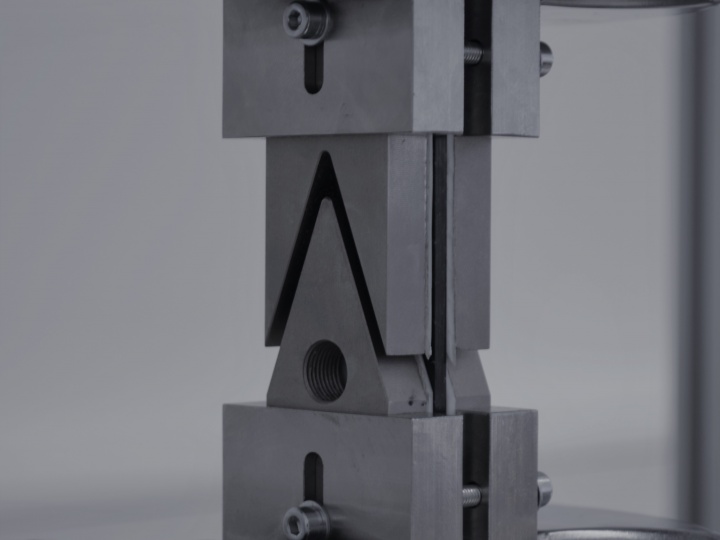

GZ IT-50

IITRI compression test fixture for quasi-static testing

The IITRI compression test fixture GZ IT-50 is suitable for the quasi-static characterisation of the compression properties of composites. The test fixture is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermoset base materials and is used for unidirectional layers and/or fabrics as well as multilayer composites (sandwich laminates). Furthermore, isotropic materials such as pure resin or adhesive resin materials can also be tested with this test fixture. The compression test fixture is required for testing fibre-reinforced plastics in order to prevent the specimen from buckling. Compared to the Celanese compression test fixture GZ C-20, the IITRI test fixture has the advantage that testing according to ASTM D3410 as well as DIN EN ISO 14126 is possible.

This means that specimens with a length of 110…160 mm and a width of 6…25 mm can be tested. According to the standards, the use of tabs is not mandatory, but recommended in order to avoid too large a stress step between the clamping area and the free test surface and consequently clamping fractures. Strain gauges are applied to the centre of the specimen on both sides in order to determine the compressive stiffness, the strain at failure and the buckling. The test fixture consists of clamping wedges which, according to the self-reinforcing principle, divert the axial force of the testing machine into a transverse force for clamping the test specimen.

- Rigid compression test fixture for static test loads up to 50 kN

- Specimen geometry 110...160 mm x 6...25 mm x 4/2 mm

- Specimen exchange within the fixture, i.e. the clamping wedges do not have to be removed for specimen exchange

- Exchangeable clamping pads for different materials and fibre orientations

- Very high quality and durable construction for easy operation to achieve smallest standard deviations

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

GZ IL-10

ILSS bending test fixture for quasi-static tests

An ILSS bending test fixture is used to determine the apparent interlaminar shear strength (ILSS). The test fixture is used for testing according to various standards on short, long and continuous fibre-reinforced plastics with thermoplastic or thermosetting base materials and is used for unidirectional layers or fabrics. In addition, isotropic materials such as pure resin or adhesive resin materials can also be tested with this test fixture.

The short beam test method is a modification of the 3-point bending test. The support distance is small in relation to the specimen thickness, which means that the specimen is loaded in shear. The specimens specified in the relevant standards differ in length, thickness and support span. The test specimen is a short beam made of a thermoplastic or thermosetting matrix with fibre reinforcement in 0° or 0°/90° direction. By apparent interlaminar shear strength the standard means “the maximum shear stress present in half the thickness of the test specimen at the moment of first failure”.

- Compact test fixture for test loads up to max. 10 kN

- Specimen geometry 20 mm x 10 mm x 2...3 mm

- Exchangeable support inserts for simple and quick adaptation of the test fixture to the respective test standard

- Precise centring of the specimen by lateral guides and setting gauge

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

GZ B-20

Bending test fixture for quasi-static tests

The innovative GZ B-20 bending test fixture enables all common bending tests on fibre-reinforced plastics to be carried out with just one test fixture. All support spans required for this can be flexibly adjusted with this test fixture. The principle of the bending test consists in the use of a two-part bending test fixture in which the specimen is clamped as a bending beam between two outer supports and loaded via an inner support (3-point bending) or two inner supports (4-point bending). For bending tests on fibre-reinforced plastics, the methods according to DIN EN ISO 14125, DIN EN ISO 178 and ASTM D790 are usually used. For this, a 3-point or 4-point load can be realised in the bending test.

By means of the various test methods for composites, the flexural strength and the flexural modulus are determined under a bending load of the test specimen at defined test conditions. The test is carried out at constant speed up to a specified deformation or until failure of the test specimen. As a result, the bending stress, the bending modulus and the elongation at failure are determined.

- Compact test fixture for test loads up to max. 20 kN

- Exchangeable support inserts for simple and quick adaptation of the test fixture to the respective test standard

- Freely adjustable support distances

- Precise centring of the specimen by lateral guides and setting gauge

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

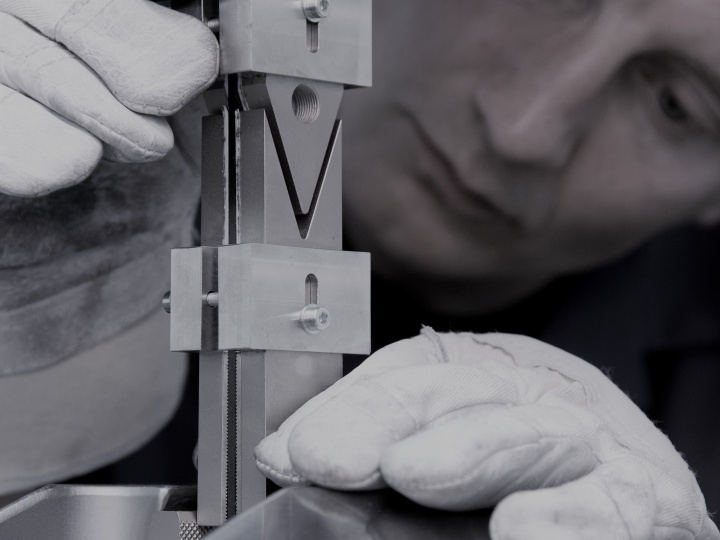

GZ BS-32

Buckling support for cyclic tests

For the performance of fatigue and load collective tests, a buckling support is used when compressive stresses occur. This buckling support is suitable for the cyclic characterisation of the tensile, compression and shear properties of fibre-reinforced plastics and can be used in all common servo-hydraulic universal testing machines or electropulsers. The testing device is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermosetting base materials and is used for unidirectional layers and/or fabrics as well as multilayer composites (sandwich laminates).

The fatigue test is carried out in accordance with the RHV guideline of the German Federal Aviation Authority or comparable standards. The specimen is clamped in the buckling support. The precise alignment takes place outside the testing machine. A clamping device prevents slippage during clamping in the testing machine. Due to the V-shaped slot in the buckling support, the cyclic tests can also be carried out for fibre orientations in the +/-45° direction for determining the shear characteristic value, where a high energy dissipation occurs. For a fibre orientation of the specimen in +/-45° direction, the cyclic shear properties are determined in single or multi-stage tests. With a fibre orientation of 0°, 90° or 0/90° direction, the cyclic tension-compression properties are tested.

- Universal buckling support for quasi-static and cyclic loads up to 50 kN

- Specimen geometry 32 mm x 1...4 mm x 210 mm

- Exchangeable clamping pads

- Friction pads made of Teflon or of a friction-optimised material

- Stainless steel design of all components for use in climatic chambers (-60...+150 °C)

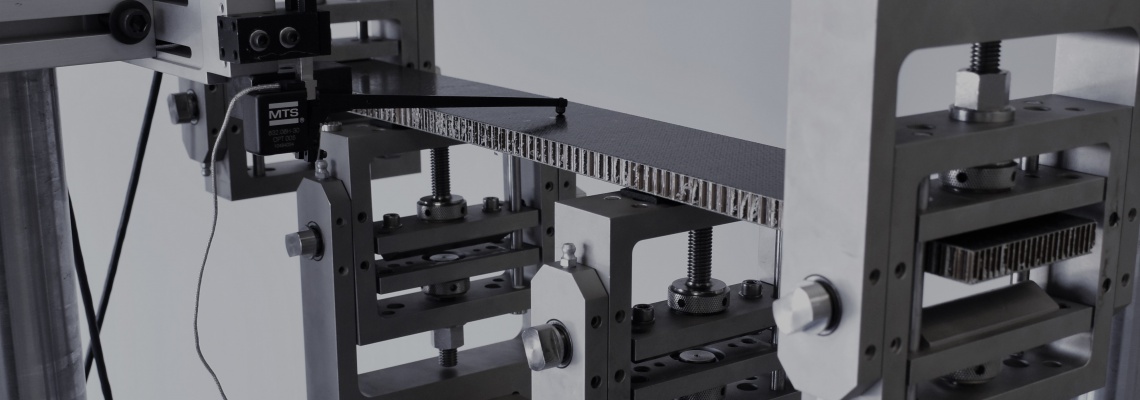

GZ B-50

3-point & 4-point flexure fixture for cyclic tests

The flexure fixture GZ B-50 is suitable for the quasi-static and cyclic characterisation of the flexural properties of fibre-reinforced plastics. The test fixture is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermoset base materials and is used for unidirectional layers and/or fabrics as well as multilayer composites (sandwich laminates).

The flexure fixture is suitable for 3-point and 4-point bending tests and can be used for both quasi-static and cyclic tests.

- Rigid flexure fixture for high static and cyclic loads up to 50 kN

- Intelligent design for easy change between 3-point and 4-point bending

- Roller bearings of the cages with large-dimension needle bearings for high load cycles with low maintenance requirements

- Vertical and horizontal centre positioning of the specimens to prevent displacement in cyclic operation

- Determination of S/N curves at load ratios of R = -1 (alternating load) or all other load ratios

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

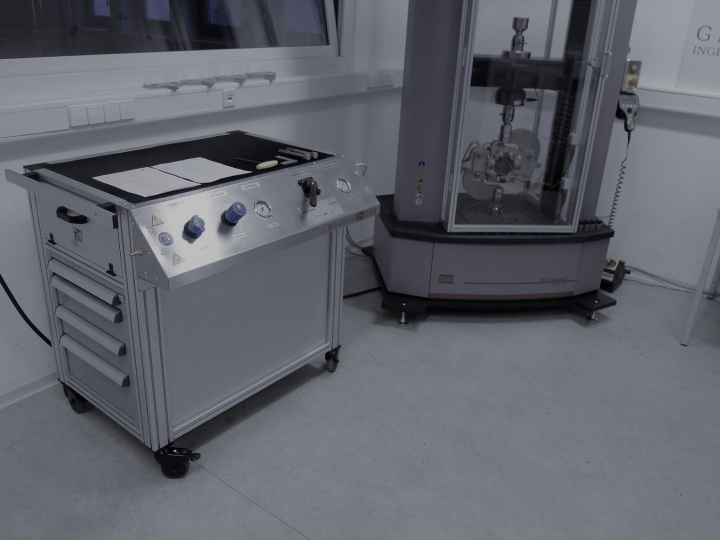

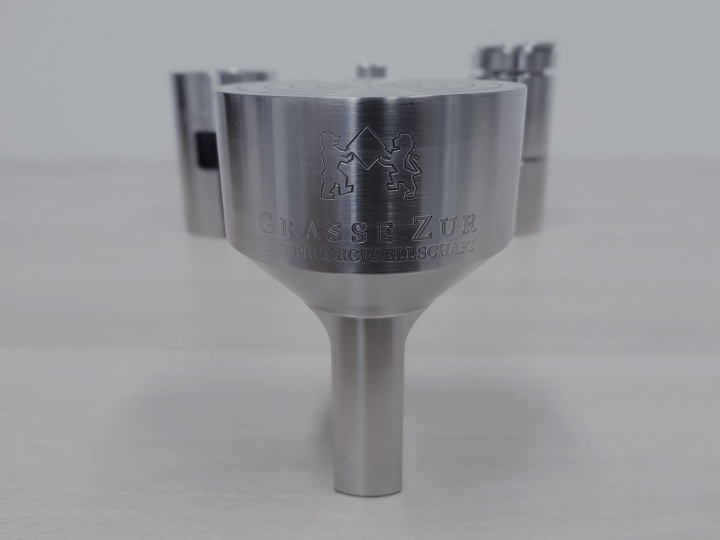

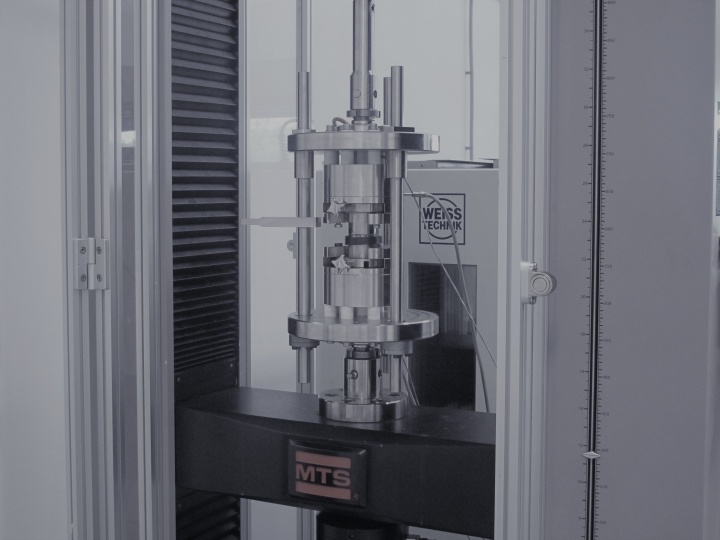

GZ RA-20

Release agent test fixture

In the manufacturing process of components made of fibre-reinforced plastics, the demouldability from the cavity has a decisive influence on the quality of the component. For demoulding, the inside of the mould is carefully prepared with release agents. In automated production, integrated release agents are used that are compounded into the thermoplastic or added to the thermoset system.

For the determination of the residual adhesive force of release agents, the test fixture GZ RA-20 was developed together with the automobile manufacturer BMW. The test fixture is suitable for use in universal testing machines. The release agent / plastic mixture to be tested is applied between two heatable plane-parallel surfaces made of high-alloy tool steel. The temperature setting and dwell time depend on the process data of the user or can be determined or optimised as part of a test series. During the test, the surfaces move apart at a defined speed, whereby the residual adhesive force generated by the polymer is measured.

In addition to the characterisation of release agents, the test fixture is also suitable for the reproducible production of pucks, which are used for further thermoanalytical or optical investigations. Furthermore, the installation of ultrasonic sensors of the US-Plus®-Technology is possible in order to be able to observe the curing process online.

- Test fixture for loads up to max. 20 kN

- Specimen geometry D 50 mm x 1...2 mm

- Quick change system of the stamps

- Maximum temperature 180 °C

- Computer-controlled temperature regulator

- Use in universal testing machines

GZ P-10

Permeation test fixture

The permeation test fixture GZ P-10 is used to determine the permeability of water vapour. It is used together with a climatic chamber. In connection with fibre-reinforced plastics, the water vapour permeability gives an indication of the permeability of these materials.

The test is particularly necessary when the material comes into contact with water.

- Precise test fixture made of CNC-turned aluminium

- Sealing with O-ring

- Holder for silica gel

GZ SD-80

Split disk test fixture for wound tubes and tube sections

The split disk test fixture GZ SD-80 is used for quasi-static and cyclic testing according to ASTM D2290. The ring tensile strength of rings, tubes and tube sections made of plastics and fibre-reinforced plastics (wound tubes) is determined. The tests are performed on test specimens over the entire width or on test specimens with a reduced cross-section to reduce the marginal influence at a defined failure location.

The split disk test fixture GZ SD-80 is characterised by very high rigidity and easy handling. The fork heads, which can be adapted to all common universal testing machines, are first installed for testing. The hinged discs are then fastened to the clevises using bolts. During the test, the disks align themselves so that the ring-shaped specimen almost completely abuts the disks and a reproducible material failure occurs. If required, strain gauges can be applied to determine the ring tensile stiffness and elongation at break. The disks are available for ring diameters in the range 50…250 mm. The test fixture is also designed for use in climatic chambers.

- Easy alignment and clamping of the test specimen

- Optimised surfaces for reproducible material testing

- Wide range of applications due to disks for ring diameters in the range 50...250 mm

- Material stainless steel

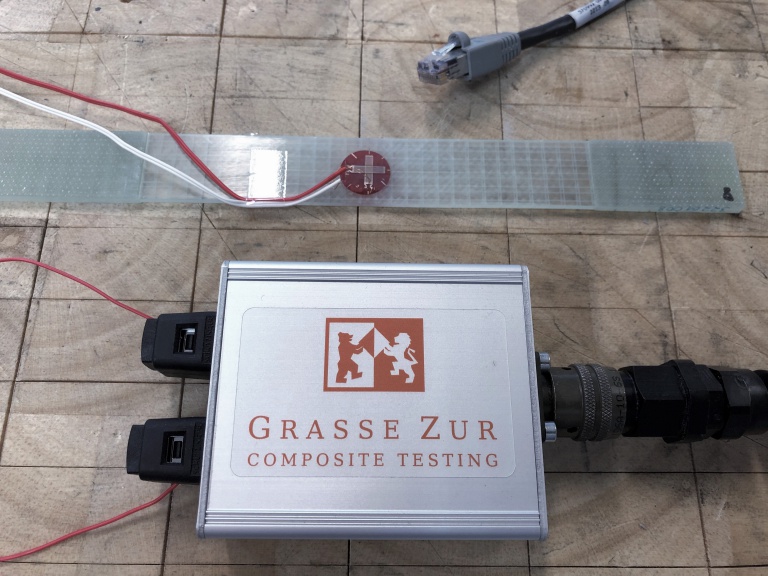

GZ DMS-2/3

Strain gauge connection kit

The strain gauge connection kit GZ DMS-2/3 is used together with universal testing machines. It is used to connect the strain gauge of the specimen to the testing machine. For this purpose, a Wheatstone bridge is required to record the small ohmic resistance changes that occur locally in the strain gauge when the specimen is strained. In the universal testing machine these resistance changes are converted into strains.

The strain gauge connection kit GZ DMS-2/3 is characterised by a very user-friendly design. It consists of two or three long-life connection terminals for connecting the strain gauges in 2-wire or 3-wire technology, which guarantee reliable contacting of the strain gauge conductors. The cable to the testing machine is connected to the strain gauge connection box via an Amphenol socket. For the Wheatstone bridge, high-quality and selected supplementary resistors are used. The strain gauge connection box is attached to the frame of the universal testing machine via magnetic feet.

- Universal connection kit for strain gauges for use with universal testing machines

- Two or three terminals for connecting the strain gauges in 2-wire or 3-wire technology

- Use of high-quality and selected resistors for the Wheatstone bridge

- Mounting of the strain gauge connection box via magnetic feet

Request Form

Please fill out the following form to receive a quotation. If the desired test fixture is not listed, please enter the fixture in the comment field. In case of deviations or special configuration requests, please use the comment field, too. After sending the request, you will receive a non-binding offer and further information from us promptly.

Your contact person

Jonathan Jancke, B.Sc.

Development Engineer

+49 30 7790791-61

jonathan.jancke@grassezur.de