Composite Bending Tests

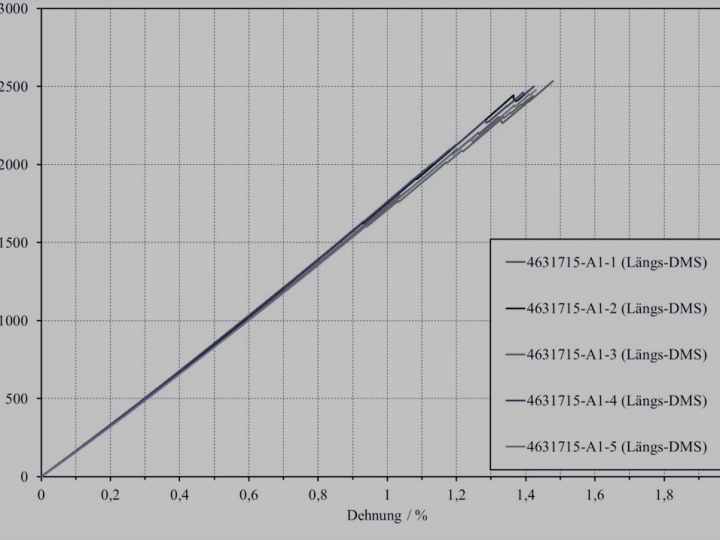

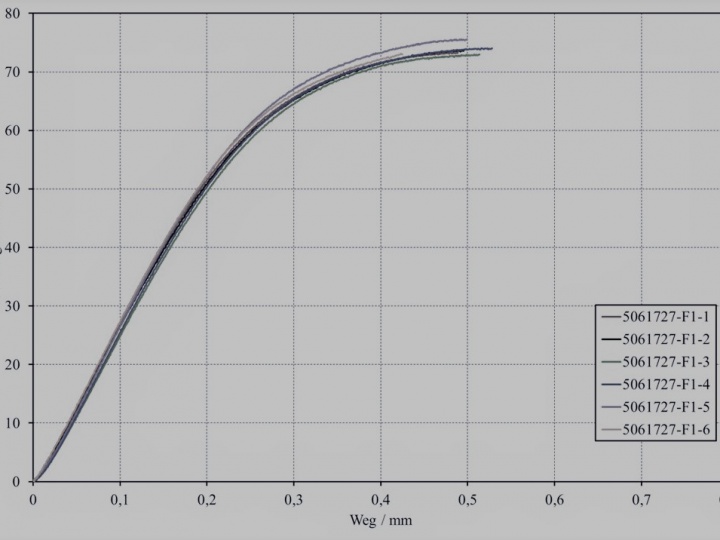

The procedures according to DIN EN ISO 14125, DIN EN ISO 178 and DIN 53293 are mostly used for the bending tests on fiber reinforced plastics (FRP) and on sandwich structures (core composites). A 3-point or 4-point load can be used for the bending test. By means of the various test methods for FRP, the bending strength and the flexural modulus are determined under a bending load of the specimen under defined test conditions. The principle of the bending test consists in a two-part bending process, in which the specimen is clamped as a bending beam between two outer supports and loaded via one (3-point) or two (4-point) inner supports. The test is carried out at a constant increasing speed to a given deformation or until the failure of the sample. As a result, the bending stress and the flexural modulus are determined.

When stressing composite or sandwich material, a 4-point bend has an advantage over the 3-point bending test. A 4-point bend has a constant expansion and a bending curve occurs between the inner supports. It should be noted that in the 4-point bending test between the outer and inner supports an additional shear stress occurs. The bearing distances, i.e. the lever arms, are to be selected so that the shear strength of the material is undercut. The test area between the inner supports is free of shear stress.