Composite Adhesive Tests

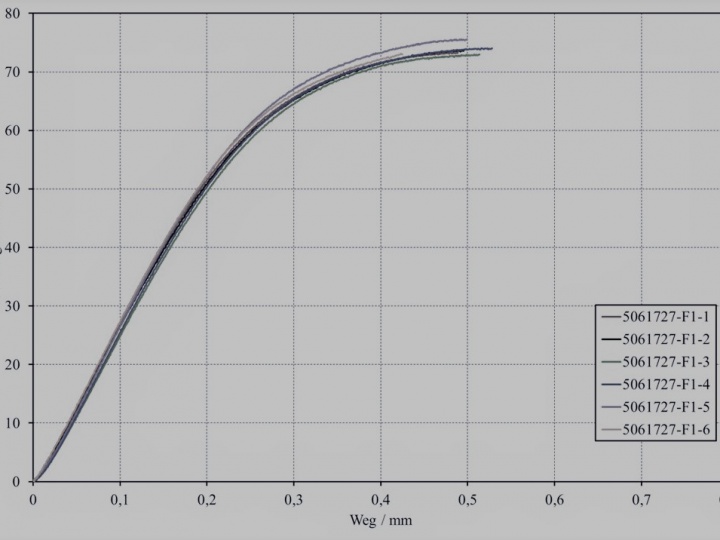

Double lap shear test according to ASTM D3528

As a rule, bonding is used as a joining method for components made of fibre-reinforced plastics and composites. These join the individual components of the parts together and must withstand the same loads as the individual structural elements made of FRP themselves. The adhesives are often based on thixotropic duromer materials (epoxy resin or vinyl ester resin systems), but permanently elastic bonds (synthetic rubbers) are also used. Other base materials are polyurethanes or cyanates, silicones and acrylates. In addition to the purely mechanical load of the adhesive systems, external influences such as UV radiation, exposed media and temperatures play a decisive role in the selection.

Decisive for proper bonding is the physical, chemical and mechanical bond (cohesion and adhesion). This can only be achieved if the individual steps of the bonding process are followed according to the general procedural instructions and in accordance with the adhesive manufacturer’s specifications. The types of stress on bonded joints can be divided into tensile stress, split stress, tensile shear stress and peel stress. Further information can be found in DIN 53281-1…3, DIN 53283, DIN 54451 and VDI 2229, among others.