Composite Sandwich Tests

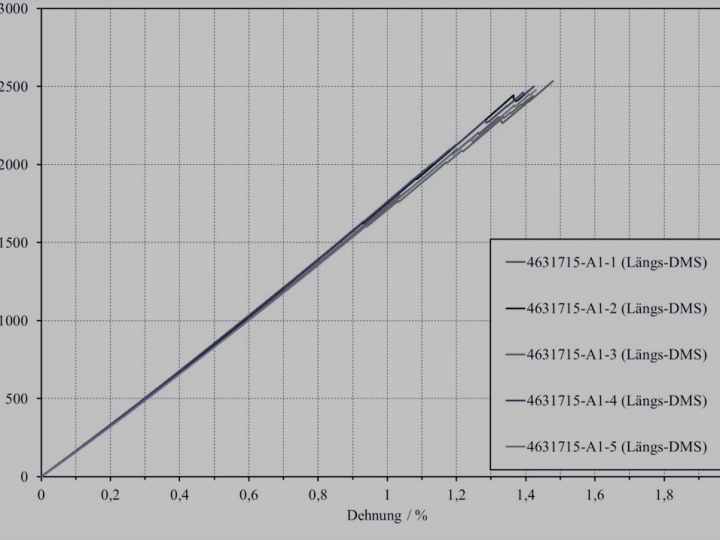

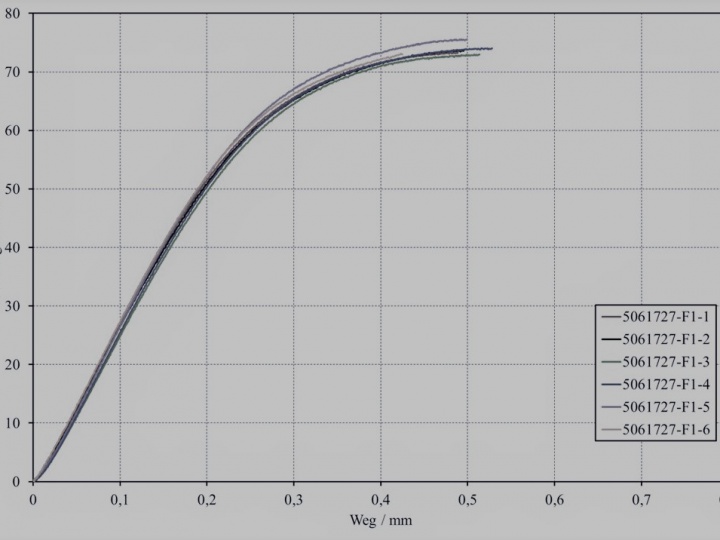

Tensile test according to DIN 53292 (sandwich structure)

Composite materials that consist of cover layers and a core material are called sandwich structures. The outer cover layers consist of two thin but stiff laminates, which are usually built up in 0° or 0°/90° fibre orientation. The core material is considerably thicker in comparison and has a significantly lower strength. By shifting the outer cover layers away from the neutral fibre, sandwich structures obtain their high flexural strength with an overall low density (exploiting the Steiner component).

Open- or closed-cell foams, e.g. made of polyurethane, polyethylene or polystyrene, are usually used for the core materials. Balsa wood or honeycomb structures made of plastic, paper or aluminium are also used. The cover layers are usually made of glass or carbon fibre reinforced plastics with thermosetting or thermoplastic matrix. The bonding of the core material with the cover layers is demanding and places special requirements on the processor due to the bending load of the structure (interlaminar shear stress in the composite).