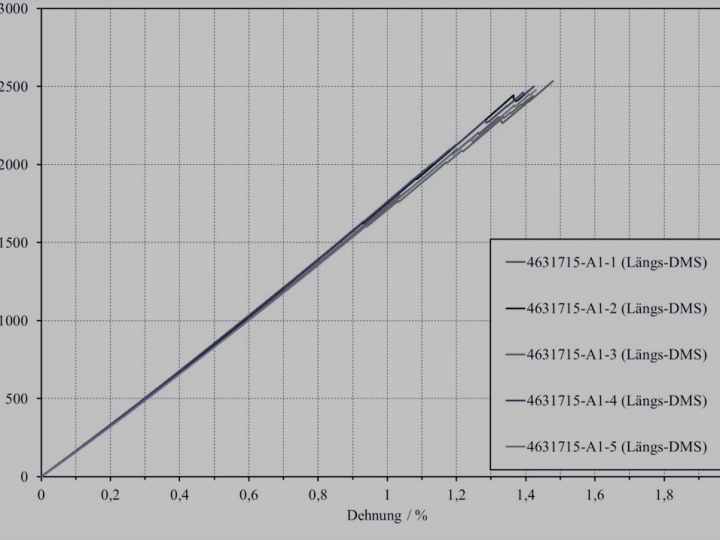

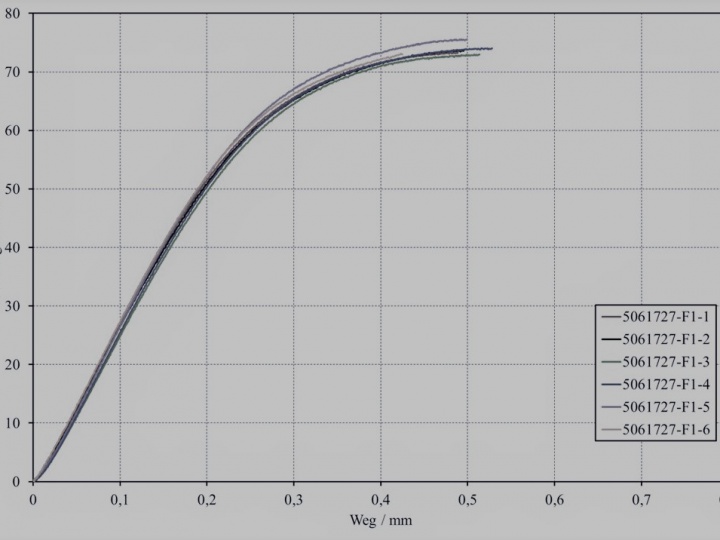

Composite Tensile Tests

Tensile test according to DIN EN 2597

In the tensile test, the mechanical material properties are determined under quasi-static tensile loading. The tensile test is one of the most commonly used test methods and is also used for composite materials such as carbon and glass fiber reinforced plastic. Basically, a distinction is made between isotropic, anisotropic and orthotropic materials. In the case of anisotropic materials, a fiber breakage load (FB) results in the fiber longitudinal direction (0° fiber orientation) and an intermediate fiber breakage load (IFB) in the fiber transverse direction (90° fiber orientation).

In order to obtain high-quality test results, a precise specimen production is of great importance in this tensile tests. Doppler with a fiber orientation of +/- 45 ° prevents unwanted failure of the specimens in the clamping area (clamping break) due to the lateral force jump. Ensuring very careful processing of the specimen edges is essential in order to avoid complex stress situations and early crack initiation. The use of diamond saw blades or CNC milling machines is state of the art. For carrying out the tests at elevated temperatures, suitable adhesives for the doublers and the strain gauges are used.