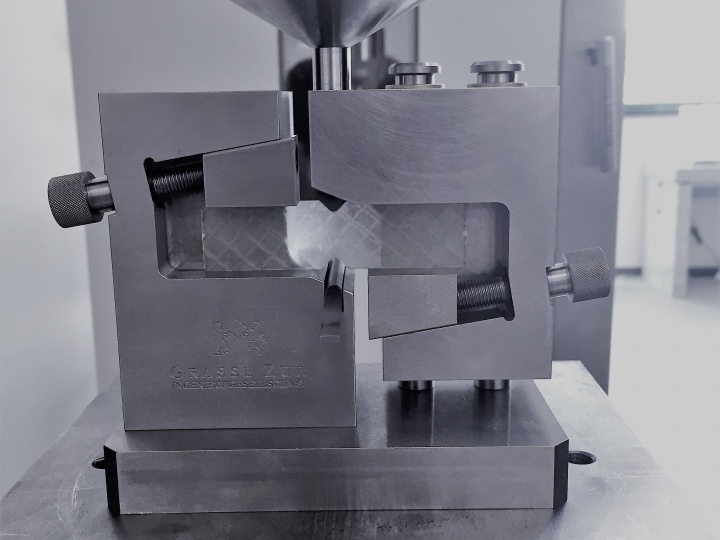

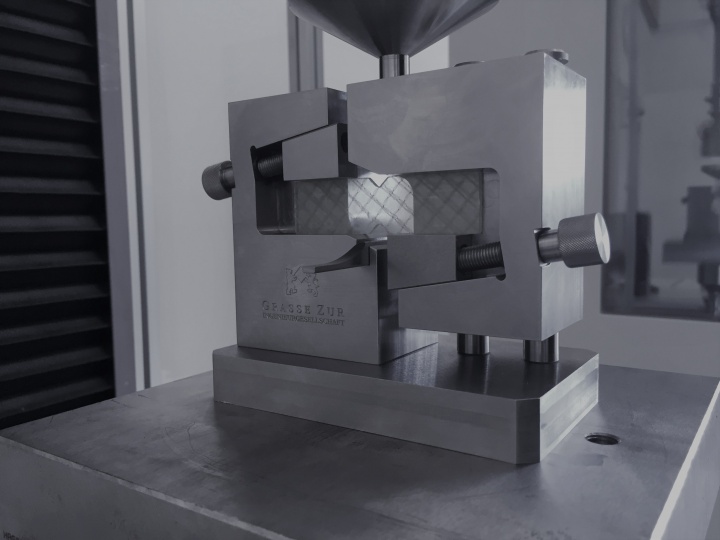

GZ IS-20

Iosipescu shear test fixture for quasi-static testing

For the performance of shear tests according to ASTM D5379, an Iosipescu shear test fixture is used, which can be used in all common universal testing machines. This shear test fixture is suitable for the static characterisation of the shear properties of fibre-reinforced plastics. The Iosipescu shear test is performed by means of an asymmetrically loaded four-point bending specimen. The specimen is clamped in the Iosipescu test fixture and loaded via two profiles that are movable relative to each other. The loads are introduced into the specimen via four areas. A V-shaped notch in the specimen determines the location of the failure. The material load in the specimen represents a shear force shear stress.

A major advantage of the Iosipescu shear test compared to other methods such as the shear tensile test according to DIN EN ISO 14129, the rail shear test according to ASTM D7078 or the picture frame shear test according to DIN EN ISO 20337 is the simple test procedure. With this test method, uniaxially and multiaxially oriented laminates with any fibre orientation can be tested with little effort. However, due to the small specimen geometry and the notch, lower shear characteristics (shear stiffness and shear strength) are usually determined.

- Compact and very high quality test fixture for test loads up to max. 20 kN

- Precise alignment and centring of the specimen by central setting gauge

- Specimen geometry 76 mm x 19 mm x 2...10 mm

- Stainless steel design of all components for use in climatic chambers (-40...+150 °C)

- Connection to all common electromechanical and servo-hydraulic universal testing machines