GZ BS-32

Buckling support for cyclic tests

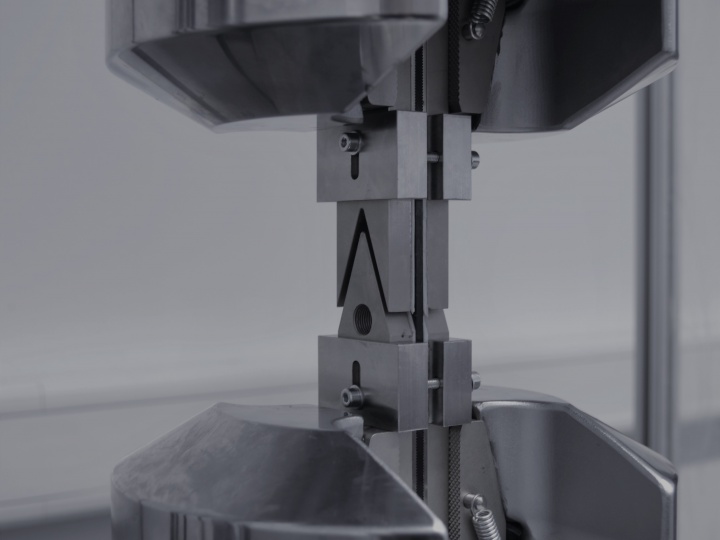

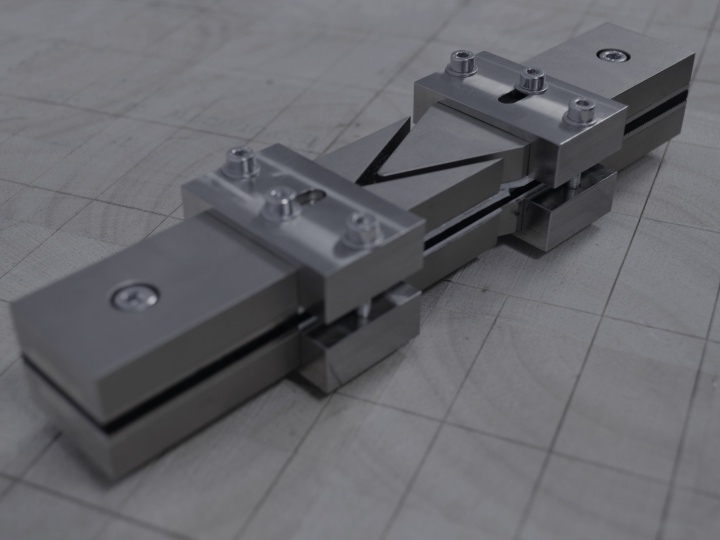

For the performance of fatigue and load collective tests, a buckling support is used when compressive stresses occur. This buckling support is suitable for the cyclic characterisation of the tensile, compression and shear properties of fibre-reinforced plastics and can be used in all common servo-hydraulic universal testing machines or electropulsers. The testing device is used for testing short, long and continuous fibre-reinforced plastics with thermoplastic or thermosetting base materials and is used for unidirectional layers and/or fabrics as well as multilayer composites (sandwich laminates).

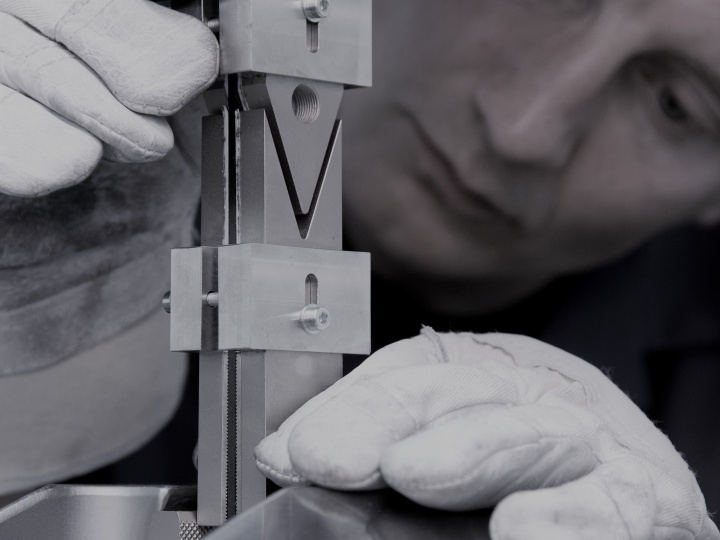

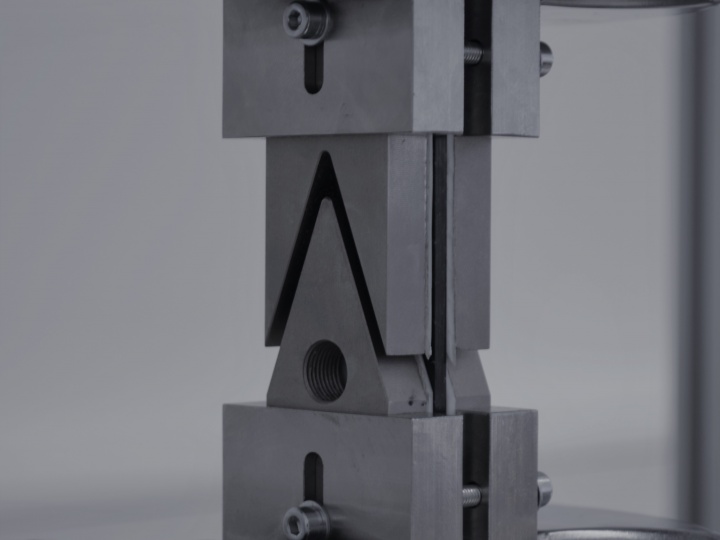

The fatigue test is carried out in accordance with the RHV guideline of the German Federal Aviation Authority or comparable standards. The specimen is clamped in the buckling support. The precise alignment takes place outside the testing machine. A clamping device prevents slippage during clamping in the testing machine. Due to the V-shaped slot in the buckling support, the cyclic tests can also be carried out for fibre orientations in the +/-45° direction for determining the shear characteristic value, where a high energy dissipation occurs. For a fibre orientation of the specimen in +/-45° direction, the cyclic shear properties are determined in single or multi-stage tests. With a fibre orientation of 0°, 90° or 0/90° direction, the cyclic tension-compression properties are tested.

- Universal buckling support for quasi-static and cyclic loads up to 50 kN

- Specimen geometry 32 mm x 1...4 mm x 210 mm

- Exchangeable clamping pads

- Friction pads made of Teflon or of a friction-optimised material

- Stainless steel design of all components for use in climatic chambers (-60...+150 °C)