GZ RA-20

Release agent test fixture

In the manufacturing process of components made of fibre-reinforced plastics, the demouldability from the cavity has a decisive influence on the quality of the component. For demoulding, the inside of the mould is carefully prepared with release agents. In automated production, integrated release agents are used that are compounded into the thermoplastic or added to the thermoset system.

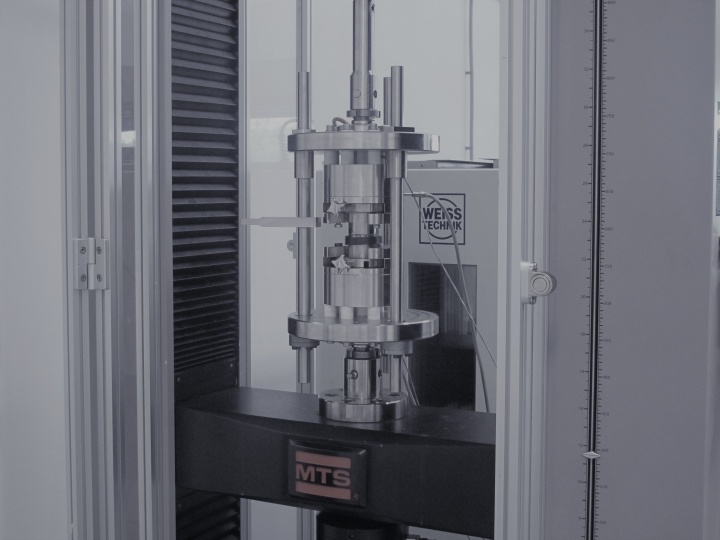

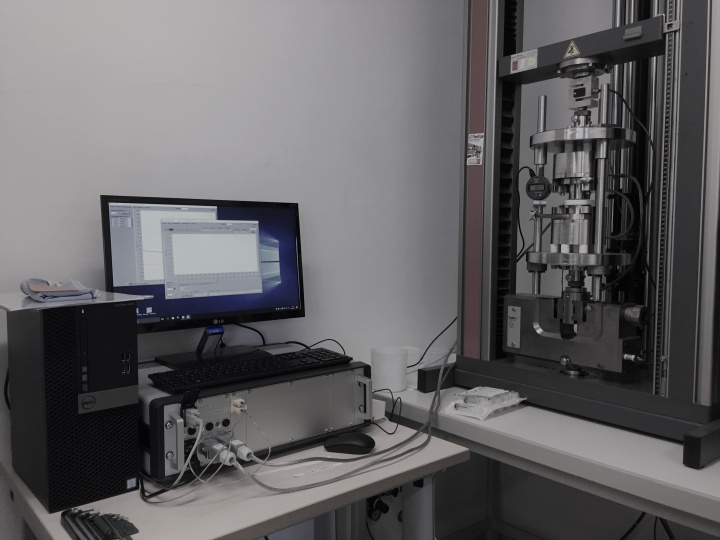

For the determination of the residual adhesive force of release agents, the test fixture GZ RA-20 was developed together with the automobile manufacturer BMW. The test fixture is suitable for use in universal testing machines. The release agent / plastic mixture to be tested is applied between two heatable plane-parallel surfaces made of high-alloy tool steel. The temperature setting and dwell time depend on the process data of the user or can be determined or optimised as part of a test series. During the test, the surfaces move apart at a defined speed, whereby the residual adhesive force generated by the polymer is measured.

In addition to the characterisation of release agents, the test fixture is also suitable for the reproducible production of pucks, which are used for further thermoanalytical or optical investigations. Furthermore, the installation of ultrasonic sensors of the US-Plus®-Technology is possible in order to be able to observe the curing process online.

- Test fixture for loads up to max. 20 kN

- Specimen geometry D 50 mm x 1...2 mm

- Quick change system of the stamps

- Maximum temperature 180 °C

- Computer-controlled temperature regulator

- Use in universal testing machines