GZ S-100 / S-100 HT

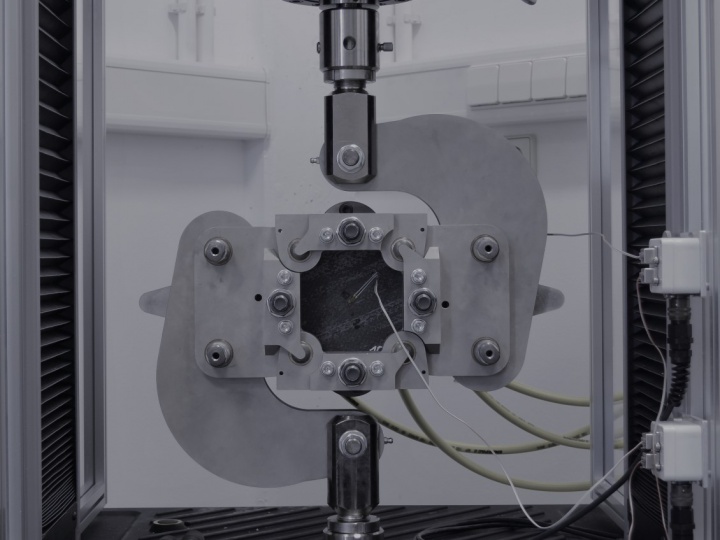

Picture frame shear test system for quasi-static tests

The picture frame shear test system GZ S-100 / GZ S-100HT is an innovative test method for the determination of shear strength and shear stiffness of fibre-reinforced plastics based on a picture frame. The determination of shear characteristics by means of a picture frame represents the reference method for the determination of shear characteristics, is standardised according to DIN EN ISO 20337 (formerly DIN SPEC 4885) and has the approval of the DNVGL for the certification of rotor blades for wind turbines (DNVGL ST-0376).

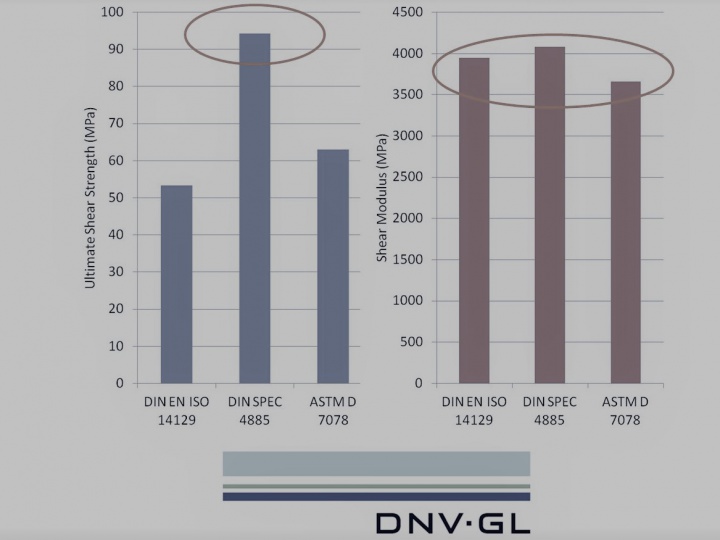

The picture frame shear test system enables a very precise determination of the shear characteristics of fibre-reinforced plastics (shear strength, shear stiffness and max. shear strain). The test method represents a significantly improved test method compared to all other shear test methods (for example DIN EN ISO 14129, ASTM D7078 or ASTM D5379), since there is a pure state of shear stress in the test specimen. For this reason, significantly higher material characteristic values are achieved with simultaneously lower standard deviations.

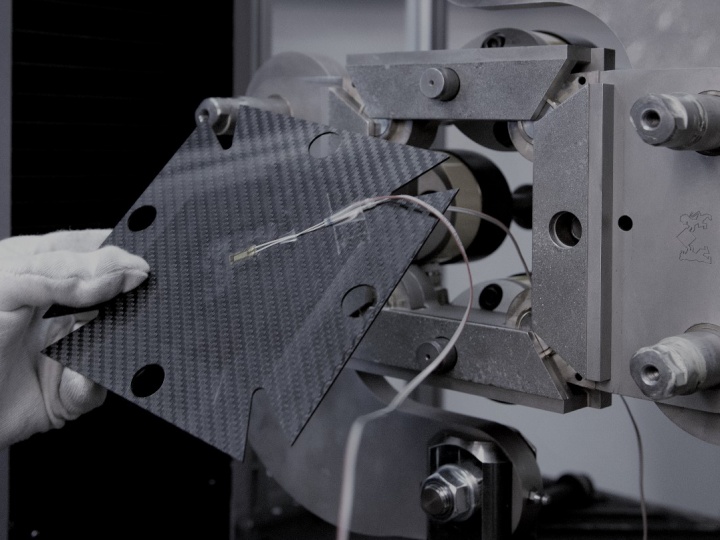

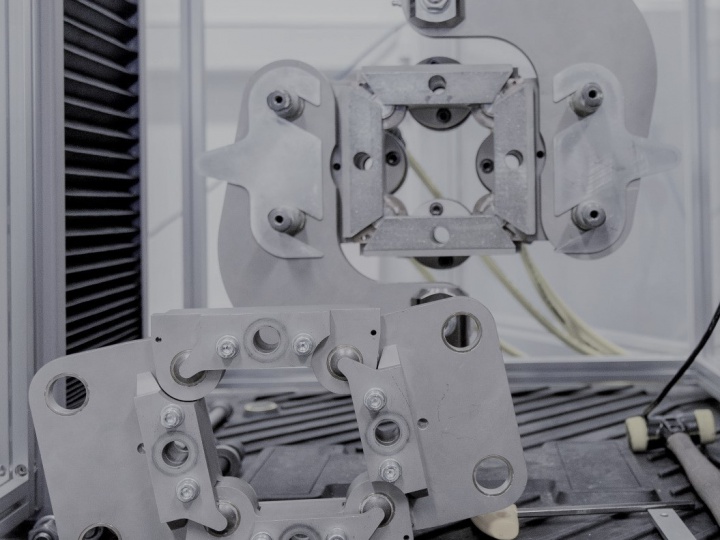

The square specimen is clamped hydraulically in the picture frame. Strain gauges are used to determine the shear strain, tabs are not necessary. Due to the split design, a simple and quick change of the test specimen within a few minutes is possible. The biggest advantage of the test method compared to other shear test methods is the non-existing limitation to max. shear strains of five percent, whereby considerably higher shear strengths are achieved. The test method was developed at the Federal Institute for Materials Research and Testing and and has been scientifically validated.

- Shear test system based on a picture frame with a unique possibility for determining the interlaminar shear properties (in-plane shear test)

- Material testing with pure shear stress state

- No free test specimen edges and no notch effects due to surface specimen clamping

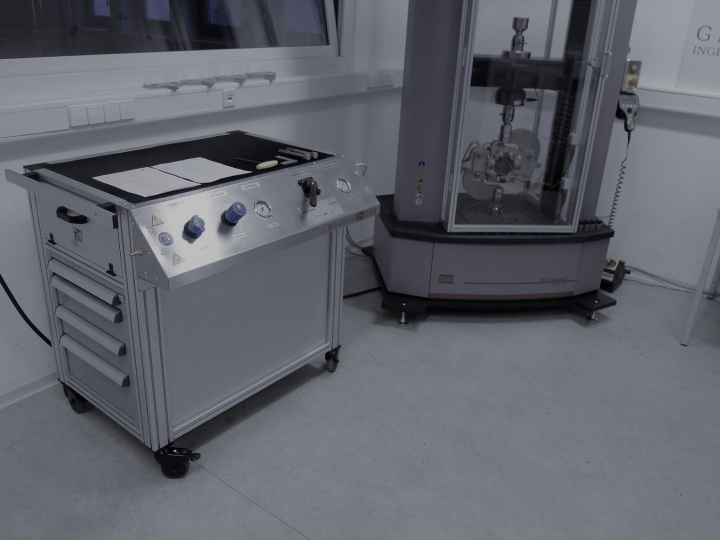

- Can be used for tests at elevated temperatures up to +150 °C (GZ S-100 HT)

- Testing of material failure and buckling behavior with test loads up to max. 100 kN

- Hydraulic test specimen clamping with homogeneous clamping distribution with max. 120 kN clamping force

- Testing of isotropic and anisotropic materials with specimen thicknesses up to max. 10 mm

- Can be used in all common universal testing machines