Composite News

Differences between the thermoanalytical methods DSC and DMA

For thermoanalytical investigations of reactive plastics such as epoxy resin systems, vinyl ester resin systems or other thermosets, the two methods DSC (Differential Scanning Calometry) and DMA (Dynamic Mechanical Analysis) are frequently used in industrial applications. These two methods differ fundamentally in their physical mode of action and in their complexity. The aim of a thermal analysis is always to obtain information about the curing state of the material under investigation. The most frequently determined parameters for thermosetting plastics are the current glass transition temperature Tg.akt, the maximum possible glass transition temperature Tg.max and the degree of cross-linking alpha. This information can be used to draw conclusions about the production quality or material reserves.

Would you like to get more information about thermal analysis on reactive plastics? Simply register for our technical seminar Proper Curing of Resin Hardener Systems Part I or Part II and learn everything you need to know about DSC, DMA, curing and process control. In addition, we carry out the relevant tests in our DIN EN ISO/IEC 17025:2018 accredited test laboratory. Contact us or use our online test request, we will be happy to provide you with a non-binding offer.

DSC

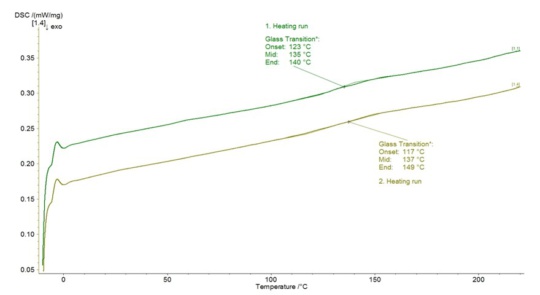

In a DSC test, a few milligrams of the material to be examined are placed in a crucible. This is examined together with an unfilled reference crucible in a DSC analyser (e.g. Netzsch, TA Instruments, Mettler Toledo,…). A typical DSC curve for a glass fibre reinforced plastic (GRP) with an EP resin system is shown below:

The advantages of a DSC analysis are mainly due to the fact that only a few milligrams of the material are needed and these components are simply taken. Specially produced test specimens are not necessary. The tests are carried out according to DIN EN ISO 11357-2, DIN EN ISO 11357-3, DIN EN 6041, DIN EN 6064 and ASTM D3418. The parameters determined are the current glass transition temperature Tg.akt, the maximum glass transition temperature Tg.max and the degree of cure alpha. A DSC analysis is relatively inexpensive due to the simplicity of the procedure.

DMA

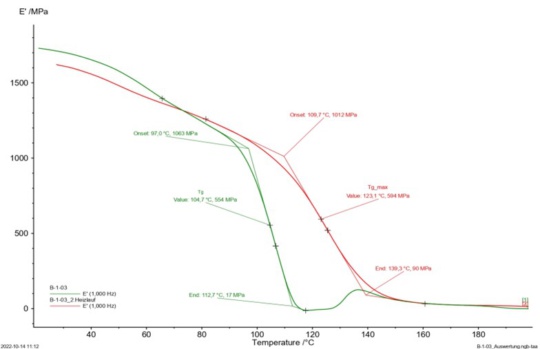

In DMA, separate test specimens are made for the analysis. These are clamped in different fixtures so that a bending, tensile or shear load can be applied while at the same time the temperature rises and the test frequency varies. The tests are carried out according to DIN EN ISO 6721-4, DIN EN ISO 6721-5 and ASTM D7028. The parameters determined are the current glass transition temperature Tg.akt, the maximum glass transition temperature Tg.max, the storage modulus E’, the loss modulus E” and the phase shift tan Delta. Below is a typical DMA curve for a glass fibre reinforced plastic (GFRP) with an EP resin system:

In principle, the characteristic values determined with a DSC analysis cannot be compared with the characteristic values determined from a DMA analysis. Especially if very precise results are required or the frequency-dependent material behaviour is also of interest, a DMA analysis is the method of choice. Compared to a DSC analysis, the procedure is more complex and expensive due to the complexity and the analysis technology.