Composite Testing Services

Test laboratory accredited according to DIN EN ISO/IEC 17025:2018

Overview

At its Berlin site, Grasse Zur Composite Testing offers a wide range of material testing according to all common test methods for fiber-reinforced plastics. The testing services are carried out in the DIN EN ISO 17025:2018 accredited laboratory and cover the entire spectrum of material testing. The clients often come from development departments (simulation or new development) or production (incoming goods or production-accompanying quality assurance) in the aerospace, automotive or chemical industries. The focus of the testing services lies equally in the quasi-static (and sometimes strain rate-development) material testing, the cyclical material testing (fatigue tests) and thermal analysis (DSC, DMA, etc.). The tests are carried out in accordance with all common test procedures according to DIN EN ISO or ASTM. Additionally, the employees of Grasse Zur have extensive know-how from many other technical fields.

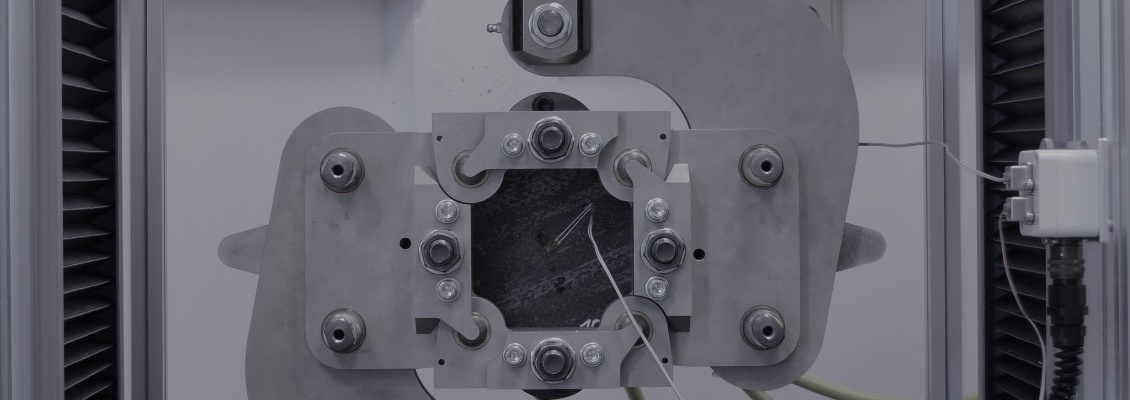

To determine the quasi-static material properties, tests are carried out on electromechanical testing machines in the force range of 1 to 100 kN. The cyclical material tests are implemented using a servo hydraulic testing machines in the force of 1 to 50 kN. The clamp is tested with flat and round hydraulic cable clamping systems (1 to 25 mm). One-stage and multi-stage fatigue tests on the servohydraulic testing machines can determine Wöhler lines and Haigh diagrams. Extensive test equipment is available for a wide variety of test requirements.

Portfolio

The range of services offered covers the complete field of material testing, from the production of laminates in the VARI process via CNC-controlled test to the execution of material testing. Optional tests include the degree of cure or fiber volume content and the conditioning of specimens and tests at different temperatures. Special test requirements, such as storage in fuels or fractographic examinations of micrographs, are implemented quickly and flexibly. The production and testing of pure resin materials from EP or VE resin systems is offered as well as drop tests for evaluation of splinter protection. Only calibrated measuring equipment is used for the tests. In accordance with aerospace requirements, only strain gauges and Poisson numbers are used to determine the moduli and to ensure accurate measurement of material deformation.

-

Order Confirmation

After quoting and commissioning, the client receives an order confirmation

-

Material Input

The material input is documented according to our accreditation ISO 17025

-

Schedule

On the day the material is received, the client will be given a detailed testing timeline

-

Test Specimen Production

Production takes place with CNC-controlled machines and possibly also includes DMS application

-

Measurement

The finished test specimens are measured with calibrated measuring equipment

-

Testing

The material testing is carried out on universal testing machines or analyzers

-

Preparation of Test Reports

The test reports contain a clear overview of the results and detailed photos

-

Dispatch of the Tested Specimens

Depending on the order, the shipment of the tested samples is securely packed

-

Summary

At the end of the test project, the client receives a clear summary of the results