Composite News

Seminar program 2023 in Berlin

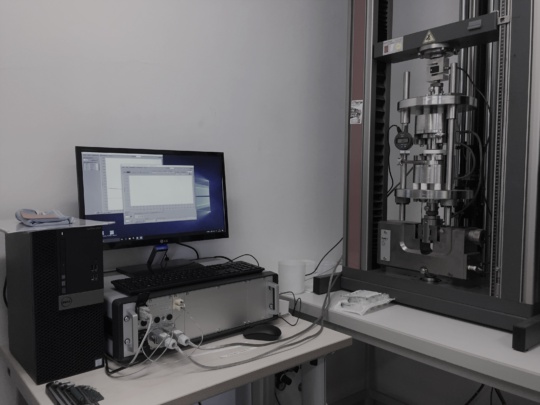

Do you or your colleagues want to learn more about composites? Would you like to refresh your knowledge around the topic testing of fiber-reinforced plastics? You would like to exchange information with other users in the field of material testing? Then you should not miss the next professional seminars at Grasse Zur Composite Testing. The seminars are aimed both at beginners and experienced material engineers:

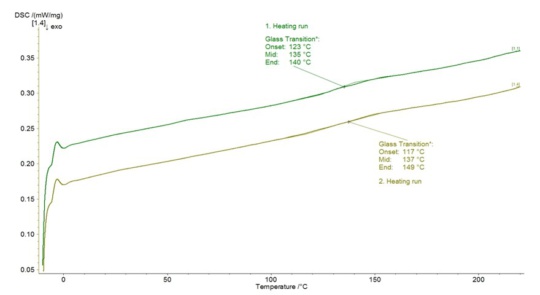

- Proper Curing of Resin-Hardener-Systems – Part I [PDF]

on 16+17 March in Berlin (focus on DSC) - Overview of Test Standards – Composites Testing! [PDF]

on 21+22 March in Berlin - Simulation of carbon components [PDF]

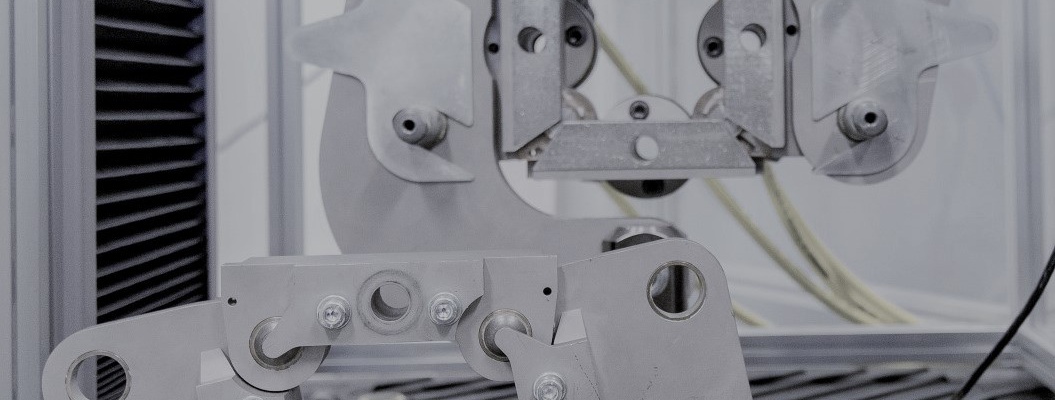

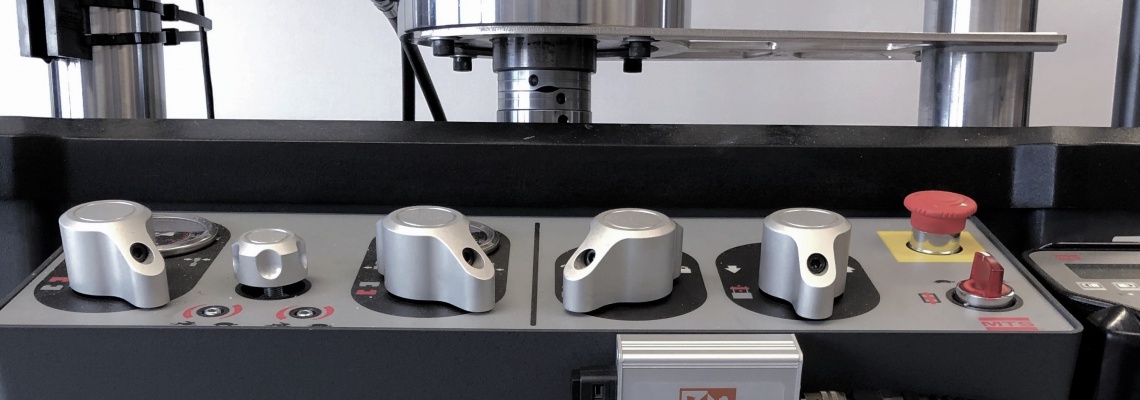

on 29+30 March in Berlin - Testing with strain gauges in theory and practice [PDF]

on 18+19 April in Berlin - Service strength & fatigue behaviour of composites [PDF]

on 18+19 April in Berli - Proper Curing of Resin-Hardener-Systems – Part II [PDF]

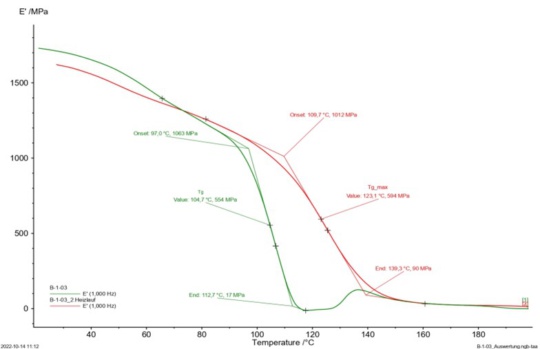

on 15+16 June in Berlin (focus on DMA, rheology, process control)

The seminars offer the time and opportunity to make contacts, introduce your everyday challenges and questions and to discuss them in the spirit of an exchange of experience. The discussions can be continued with the dinner together in a pleasant atmosphere.

For members of Composites United e.V. the price is EUR 990.00 instead of EUR 1,090.00. If more than two employees come from one company, we can grant you a small quantity discount. We also offer a discount for student and academic staff. Simply contact us. Afterwards, you can extend your stay with an interesting weekend in the capital city of Berlin.

Early bird discount

If you enter discount in the comment field when booking professional seminars by 15.02.2023, you will receive a discount of EUR 100 per participant. This discount applies to all bookings made by 15.02.2023. Please note that from 01.01.2023 new prices will apply for the specialist seminars and training courses.