Composite News

Picture Frame Shear Test for Determination of Shear Values of Composites

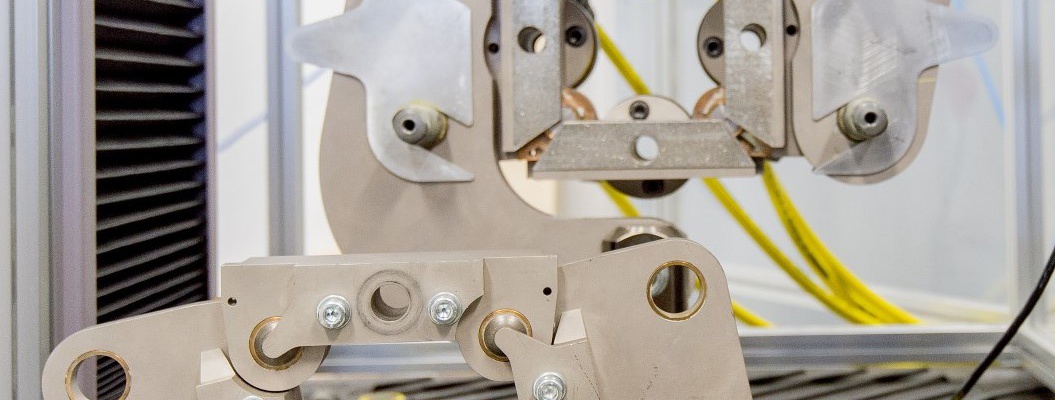

Now available: The newly developed shear frame of Grasse Zur Composite Testing for composite testing.

- Made to operate with standard tensile testing machines (Zwick, Instron, MTS, etc.)

- Shear frame for quasi-static material characterization

- Considerably improved method for the determination of shear values compared to ASTM D4255, ASTM D7078, DIN EN ISO 14129 etc.

- Testing of specimen up to 10 mm in thickness

- Testing of failure and buckling behaviour possible due to testing of very high shear flow

Grasse Zur Composite Testing offers products and services for material testings of composite materials like glass or carbon fibre reinforced plastice (GFRP or CFRP). For quasi-static shear testing of fibre reinforced plasics we developed a shear frame which provides much more accurate determination of shear properties compared to currently existing standards (DIN EN ISO 14129, ASTM D4255, ASTM D7078).

Based on the advantages of the design of the shear frame, it was used by the Federal Institute for Materials Research and Testing for extensive investigations of shear properties. The homogeneous shear stress distribution in particular as well as the firm clamping of the fibre endings at the rims of the specimen and the possibility of testing arbitrary fibre orientations sum up the decisive quality advantages.

The shear frame provides a large shear area beneficially using only limited clamping and testing forces:

- Small standard deviation of testing results

- More accurate determination of characteristic values due to higher resolution of shear area

- Smaller influence of inaccuracies in production

- Smaller influence of rims

- Smaller influence of inhomogeneity due to clamping

A hydraulic tensioning systems supplies the clampings of the specimen with the needed clamping forces. The trick: You do not need an extra hydraulic unit as the hydraulic pressure will be generated by the provided pneumatic hydraulic system. Thus shear testings until failure can be done for shear flows up to 950 N/mm and test forces up to 100 kN.

The novel, very accurate testing method of the shear frame is ideally suitable for material characterizations, research and development and quality control. Component designing or FEM simulating require very accurate material values and by thus depend on very accurate determination of material values.

Please contact us, we gladly discuss the opportunities and advantages of our shear frame with you.