Grasse Zur Composite Testing will be around again, at the most important trade fair concerning the composite industry sector in Germany and beyond: At the Composites Europe international researchers, developers and decision makers meet the users of the composites industry. It will be focused on the key technologies as well as applications: Automotive, aerospace, lightweight construction, wind energy and many more. From September 17 to 19, 2013, Composite Europe exhibits the complete process chain of composite materials – starting with from raw material to semi-finished product and from processing to the latest technologies, machines and services.

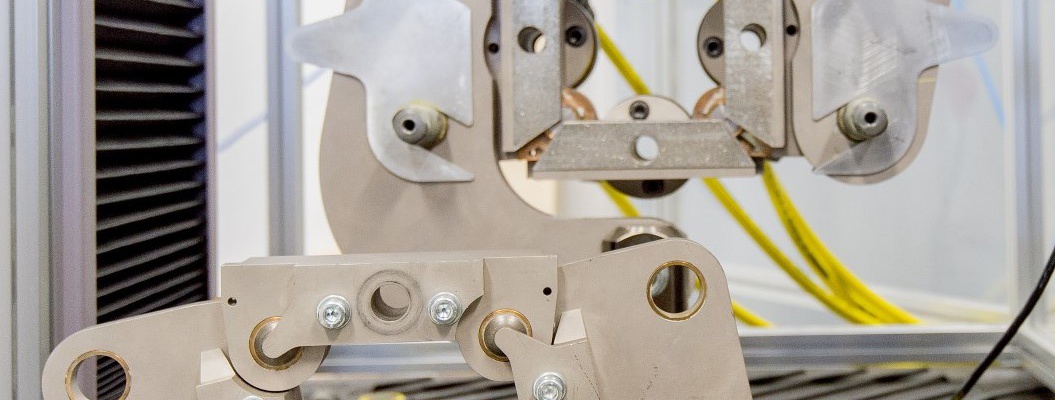

Grasse Zur Composite Testing develops and distributes novel testing systems for the characterization and measuring of fibre reinforced composite materials. The systems are used for industrial research and development, in order to ideally dimension parts and components, for quality control during processing and for incoming goods inspection.